2026 Top Robotic Arc Welding Technologies and Trends?

In the evolving landscape of manufacturing, robotic arc welding is at the forefront of innovation. Experts, like Dr. Jane Smith from the Robotics Institute, emphasize its importance, stating, “Robotic arc welding enhances precision and productivity but also presents unique challenges.”

With advancements in technology, robotic arc welding systems are becoming more sophisticated. They now incorporate artificial intelligence and machine learning to improve quality control. However, many companies still struggle with the integration of these technologies into existing workflows.

The trends of 2026 highlight a growing reliance on automation in welding processes. Companies face the dilemma of balancing investment costs with potential savings. While robotic arc welding offers significant benefits, realizing its full potential demands careful planning and consideration of human factors. This industry stands at a crossroads, where the future is bright yet complex.

Emerging Technologies in Robotic Arc Welding for 2026

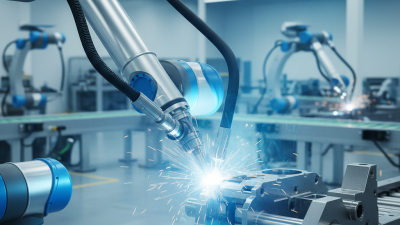

Robotic arc welding continues to evolve, with several emerging technologies set to shape its landscape in 2026. One significant trend is the rise of artificial intelligence in welding processes. AI can analyze real-time data, allowing for adjustments on the fly. This leads to enhanced precision and efficiency, minimizing human error. However, the challenge lies in ensuring these systems are adaptable to various welding scenarios.

Another intriguing development is the integration of advanced materials. New alloys are being introduced, posing questions about compatibility with existing welding techniques. While these materials offer benefits like increased strength, they can complicate the welding process. Additionally, operators may require specialized training to handle these innovations effectively. There's also ongoing debate about the education gap in understanding these materials and their implications.

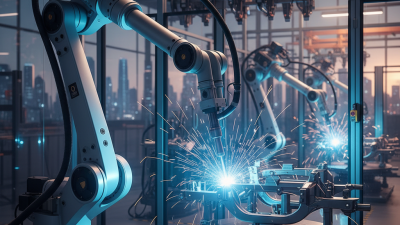

Automation is becoming more sophisticated, with collaborative robots (cobots) entering the workspace. These robots can work alongside human welders, making the process safer and more efficient. Still, the effectiveness of these machines can vary depending on the environment. Companies must reflect on how to balance human skills with automation. As robotic welding tech advances, adapting to these changes is crucial.

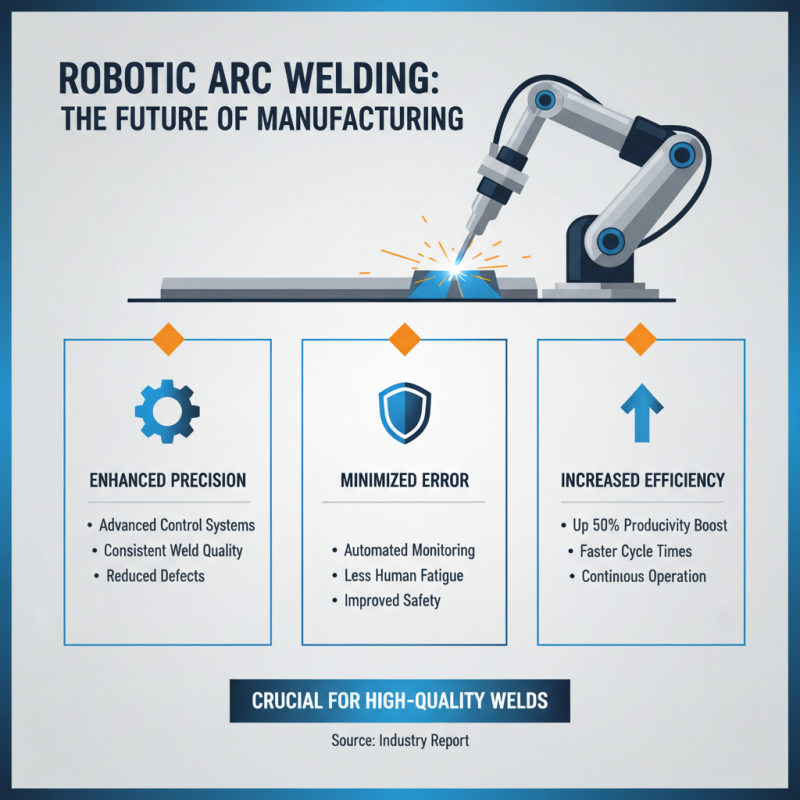

Advancements in Automation and Control Systems for Welders

Advancements in automation and control systems have greatly transformed robotic arc welding. These systems enhance precision, reduce human error, and increase efficiency. According to a recent industry report, automated welding can improve productivity by up to 50%. Such enhancements are crucial for industries demanding high-quality welds.

Modern welding robots now employ intelligent sensors. These sensors adapt in real-time, ensuring optimal performance. A study showed that weld quality significantly improves with advanced monitoring systems. The data analysis capabilities of these systems help identify potential issues before they escalate, allowing for proactive adjustments.

Despite these advancements, challenges remain. The initial setup and calibration of these systems can be complex. Many companies struggle to integrate new technologies seamlessly into existing workflows. Continuous training is essential for operators to fully leverage these systems. The balance between technology and skilled labor becomes a point of reflection for the industry. As automation grows, the need for human oversight remains critical.

Trends in Material Handling and Workpiece Positioning in Welding

In the evolving landscape of robotic arc welding, material handling and workpiece positioning present critical challenges. According to industry reports, companies are increasingly adopting automated solutions to streamline these processes. Recent data indicates that about 72% of manufacturers acknowledge the significance of accurate positioning in improving welding efficiency.

Improper material handling can lead to defects in welds. Many operators face difficulties in aligning workpieces consistently. Some studies suggest that more than 30% of weld failures can be traced back to inadequate positioning techniques. As a result, investment in advanced handling systems is essential. Yet, many facilities hesitate due to cost concerns. The balance between efficiency and investment remains a focal point for manufacturers.

Emerging technologies are reshaping how welding tasks are approached. Innovations like real-time monitoring and AI-driven adjustments can enhance positioning accuracy. However, the integration of such systems is often met with resistance. Workers may feel threatened by automation. Training must evolve alongside technology to ensure everyone adapts. It’s a complex interplay that requires thoughtful consideration.

The Role of Artificial Intelligence in Robotic Welding Processes

The integration of artificial intelligence (AI) in robotic arc welding processes is revolutionizing the manufacturing landscape. AI algorithms can analyze welding data quickly. This capability improves weld quality and reduces defects. For example, real-time monitoring can adjust parameters instantly. This leads to optimal weld production.

Tips: Always collect detailed data from your welding processes. This information will enhance your AI models over time. Regularly update algorithms to tackle new challenges and improve efficiency.

Moreover, AI can predict equipment failures before they happen. Predictive maintenance ensures the robotics are always operational. However, reliance on AI has its drawbacks. Overfitting models can lead to inaccuracies. It's essential to maintain a balance between using AI insights and human judgment. Don't ignore the importance of hands-on experience; it still matters immensely.

Tips: Use hybrid approaches that combine AI and human expertise. This strategy may produce better outcomes. Training employees to work with AI tools is equally crucial.

2026 Top Robotic Arc Welding Technologies and Trends

| Technology | AI Integration | Advantages | Challenges | Future Trends |

|---|---|---|---|---|

| Adaptive Control Systems | Enhanced precision and real-time adjustments | Improved weld quality, reduced defects | Higher initial setup cost, complexity | Increased adoption of machine learning algorithms |

| Collaborative Robots (Cobots) | AI for safety and efficiency | Flexibility in production environments | Limited payload capacity, speed | Growing use in small to medium enterprises |

| Real-Time Monitoring Systems | AI for predictive maintenance | Minimized downtime, proactive problem resolution | Requires robust data infrastructure | Integration with Industry 4.0 advancements |

| Automated Weld Inspection | AI for image analysis | Higher accuracy in defect detection | High setup cost for advanced systems | More reliance on automation for quality assurance |

| Virtual Welding Simulators | AI-enhanced training programs | Safe training environment, cost-effective | Limited to software capabilities | Increasing use in operator training and evaluation |

Future Applications and Market Growth Projections for Robotic Welding

Robotic welding is evolving rapidly. As industries seek greater efficiency, the demand for robotic welding technology is increasing. Companies aim to enhance productivity while reducing labor costs. The market is projected to grow significantly by 2026. Trends in automation will drive this growth. Many sectors, such as automotive and aerospace, are leading the way.

Future applications of robotic welding are diverse. These robots are increasingly used for complex tasks. For example, in the construction of heavy machinery, they provide precise welds. Yet, challenges remain. Integrating advanced robotic systems requires skilled personnel. Training programs must keep pace with technology. Moreover, maintenance of robotic systems can become costly over time.

Market trends suggest a shift towards collaborative robots. These robots work alongside human operators. They enhance safety and flexibility in the workspace. However, there is skepticism about job displacement. Balancing automation with human labor is crucial. The future of robotic welding will require reflection on these issues. Investing in workforce development will be essential as technology transforms the landscape.

2026 Top Robotic Arc Welding Technologies and Trends

Related Posts

-

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

How to Master Robotic Arc Welding: Tips, Techniques, and Best Practices

-

2025 Guide: How to Optimize Robotic Arc Welding for Maximum Efficiency

-

Why Is Seam Tracking Welding Essential for Precision in Modern Manufacturing?

-

Top 10 Benefits of Robotic Arc Welding for Modern Manufacturing