7 Best 3D Vision Systems for Robots: Enhance Automation & Efficiency

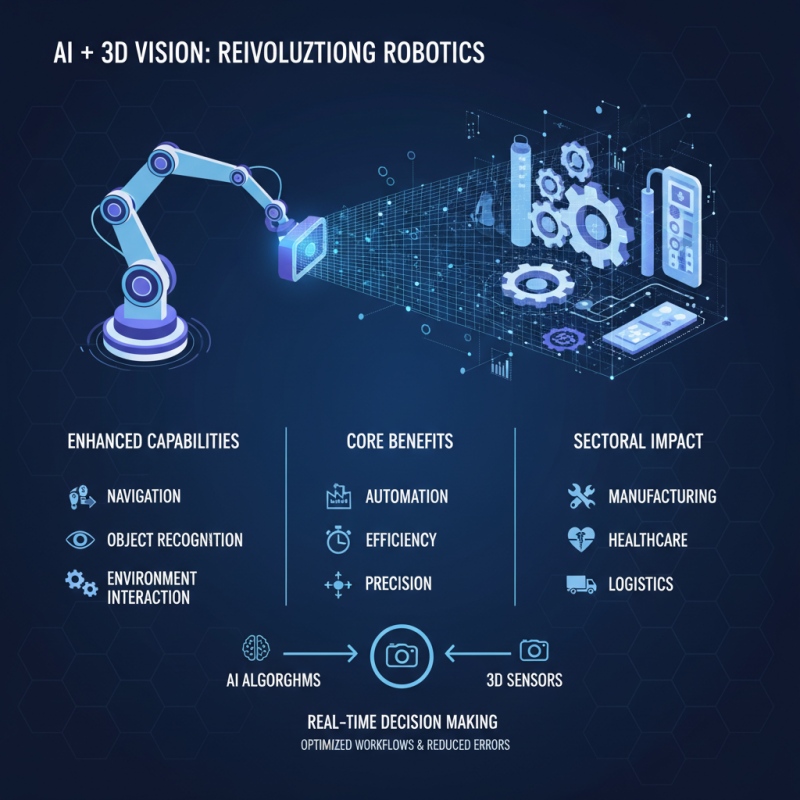

In the rapidly evolving landscape of automation, the adoption of 3D vision systems for robots has become a pivotal factor in enhancing efficiency and precision across various industries. Dr. Alex Johnson, a renowned expert in robotic vision technology, emphasizes the critical role these systems play in modern robotics, stating, "3D vision systems for robots are not just an advancement; they are the cornerstone of intelligent automation." This statement underscores the transformative impact that robust visual perception capabilities have on robotic functionality, enabling machines to interact with their environments in sophisticated ways.

As companies strive to streamline their operations and improve productivity, the integration of 3D vision systems for robots is proving essential. These systems allow robots to perceive depth and spatial relationships, thereby facilitating tasks ranging from complex assembly processes to intricate quality control inspections. By enabling machines to see and interpret their surroundings with remarkable accuracy, businesses can achieve higher levels of automation while reducing human error.

In this exploration of the best 3D vision systems for robots, we delve into the innovative technologies that are setting new standards for efficiency and reliability in automation. By understanding the landscape of these advanced systems, organizations can make informed decisions that enhance their operational capabilities and drive success in an increasingly competitive market.

Overview of 3D Vision Systems in Robotics and Their Importance

In the realm of robotics, 3D vision systems play a critical role in enhancing automation and efficiency. These systems significantly improve a robot's ability to perceive its environment, allowing for more accurate manipulation and interaction with objects. According to a recent industry report, the global market for 3D vision systems is projected to reach approximately $1.5 billion by 2025, driven by increasing demand across various sectors such as manufacturing, healthcare, and logistics. With capabilities like depth perception and object recognition, 3D vision enables robots to perform complex tasks that were previously thought impossible.

Implementing 3D vision can lead to substantial operational improvements. Organizations that integrate this technology often report reductions in production cycle times by up to 30%. Moreover, quality control processes become more efficient as robots equipped with 3D vision can identify defects faster than traditional methods. This technological advancement not only increases productivity but also enhances product quality, making it a pivotal factor in today’s competitive landscape.

Tips: When considering the integration of 3D vision systems, focus on selecting compatible sensors and processing units that align with your operational needs. Additionally, training staff to effectively implement and troubleshoot this technology can maximize efficiency gains. Regular updates and maintenance of the systems are also essential to ensure optimal performance and reliability.

Key Technologies Behind 3D Vision Systems: Sensors, Cameras, and Algorithms

3D vision systems have become essential for enhancing automation and efficiency in robotic applications, leveraging advanced technologies that include specialized sensors, high-resolution cameras, and sophisticated algorithms. Sensors play a critical role in these systems, as they capture spatial information in real time. They can be categorized into various types, such as laser triangulation, structured light, and time-of-flight sensors, each offering unique advantages depending on the application. By accurately measuring the distance and dimensions of objects, these sensors enable robots to perceive their environment in three dimensions, thus facilitating complex tasks such as object recognition, navigation, and manipulation.

Complementing the sensors, high-performance cameras are vital for capturing detailed images that support 3D reconstruction. These cameras often incorporate advanced imaging techniques, such as stereo vision, where two or more cameras work in tandem to analyze depth information from multiple perspectives. The role of algorithms is equally crucial; they process the data gathered from sensors and cameras to extract meaningful insights. Machine learning and computer vision algorithms are commonly used to interpret visual data, classify objects, and enable robots to make informed decisions. Together, these technologies foster a more intelligent and responsive robotic system, paving the way for enhanced automation across various industries.

7 Best 3D Vision Systems for Robots: Enhance Automation & Efficiency

| System Name | Sensor Type | Camera Resolution | Frame Rate (fps) | Key Algorithm |

|---|---|---|---|---|

| 3D Laser Scanner | Laser | 2048 x 2048 | 30 | Point Cloud Processing |

| Stereo Vision System | CMOS | 1280 x 720 | 60 | Depth Map Generation |

| Time-of-Flight Camera | ToF | 1920 x 1080 | 120 | Time Measurement |

| Structured Light System | LCD Projector | 2560 x 1600 | 30 | Pattern Matching |

| Photogrammetry System | Digital Camera | 6000 x 4000 | N/A | Image Matching |

| Machine Vision System | Monochrome | 1920 x 1080 | 50 | Feature Detection |

| RGB-D Camera | RGB + Depth | 1280 x 720 | 30 | Simultaneous Localization and Mapping (SLAM) |

Top 7 3D Vision Systems: Features, Specifications, and Use Cases

3D vision systems have become crucial in the realm of robotics, enhancing automation and efficiency across various industries. These systems leverage advanced imaging technologies, enabling robots to perceive their environment in three dimensions. Key features often include high-resolution image capture, depth perception capabilities, and real-time data processing. This sophisticated technology allows robots to navigate complex environments, recognize objects, and make informed decisions, significantly reducing the risk of errors in task execution.

In terms of specifications, leading 3D vision systems typically offer a range of resolutions, frame rates, and connectivity options to cater to different applications. Some systems are optimized for indoor environments, while others are designed to function seamlessly outdoors. Use cases for these systems are vast, spanning from manufacturing and logistics to healthcare and agriculture. For instance, in manufacturing, robots equipped with 3D vision can perform quality checks by accurately assessing component dimensions, while in agriculture, they can assist in harvesting by identifying ripe fruits with precision. Overall, the integration of 3D vision technology into robotic systems leads to enhanced productivity and improved operational efficiency.

7 Best 3D Vision Systems for Robots: Performance Comparison

This chart compares the accuracy and processing speed of the top 7 3D vision systems for robots. The accuracy is measured in percentage, while processing speed is measured in milliseconds.

Impact of 3D Vision Systems on Automation Efficiency and Productivity

The integration of 3D vision systems in robotics has revolutionized the landscape of automation by significantly enhancing efficiency and productivity. These advanced systems allow robots to perceive their environments in three dimensions, enabling them to perform complex tasks with greater accuracy. From bin picking in warehouses to precision assembly in manufacturing lines, 3D vision systems empower robots to act more autonomously, reducing the need for human intervention and minimizing the risk of errors.

**Tips:** When implementing 3D vision systems, consider the specific requirements of your automation processes. Selecting the right camera and sensor technology tailored to the task can drastically improve performance. Moreover, training algorithms to recognize different objects and environments will enhance the system's adaptability and effectiveness.

In addition to improving accuracy, 3D vision systems also optimize workflow by allowing robots to make real-time decisions based on visual feedback. This capability leads to shorter cycle times and increased throughput, as robots can adjust their actions on-the-fly without waiting for external input. Emphasizing continuous learning and system updates can further enhance productivity as new tasks and challenges arise.

**Tips:** Regularly evaluate the performance of your 3D vision systems and update software algorithms to adapt to evolving tasks. Investing in staff training on the latest technological advancements can also ensure that your team remains efficient in capitalizing on these tools.

Future Trends in 3D Vision Technology: AI Integration and Robotics Advancements

The integration of artificial intelligence (AI) into 3D vision technology is poised to revolutionize robotics, driving automation and efficiency to new heights. As robots equipped with advanced 3D vision systems begin to operate in various sectors—from manufacturing to healthcare—they leverage AI algorithms to interpret complex visual data in real-time. This enables robots to make informed decisions quickly, thereby enhancing their ability to navigate, recognize objects, and interact with their environment more effectively. The synergy between AI and 3D vision not only optimizes operational workflows but also reduces the likelihood of errors, ensuring higher precision in tasks ranging from assembly to quality control.

Looking ahead, the advancements in 3D vision technology will likely focus on improving perception capabilities through machine learning and neural networks. This evolution will allow robots to learn from their experiences, adapt to variable conditions, and understand dynamic environments better. Furthermore, as these 3D vision systems become more sophisticated, we can expect enhancements in depth perception and spatial awareness, granting robots the ability to execute complex maneuvers and tasks in unstructured settings. The ongoing development in this field signals a promising future where robots will play increasingly vital roles across diverse industries, leveraging AI to offer unmatched efficiency and productivity improvements.

Related Posts

-

Top Robotic Vision Technologies Transforming Industries Today

-

Revolutionizing Metal Fabrication with Seam Tracking Welding Technology for Precision Parts Production

-

Top 10 Tips for Choosing the Right Inspection Robot for Your Industry

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

How to Choose the Right Inspection Robot for Your Industry Needs

-

Robotic Process Innovations at the 138th Canton Fair 2025 Transforming Industry Standards in China