Top 10 Benefits of Robotic Arc Welding for Modern Manufacturing

In the fast-evolving landscape of modern manufacturing, robotic arc welding has emerged as a transformative force, revolutionizing the way industries approach metal fabrication and assembly. This advanced welding technique, which utilizes automated robotic systems to perform arc welding tasks, offers a myriad of benefits that enhance productivity, precision, and safety. By integrating robotic arc welding into manufacturing processes, companies can achieve higher levels of efficiency and consistency, ultimately driving down costs while bolstering product quality.

The adoption of robotic arc welding not only streamlines operations but also addresses the growing demand for flexibility in production lines. As industries strive to meet diverse customer needs and rapidly changing market conditions, the ability to quickly adapt welding processes becomes crucial. Furthermore, this technology significantly reduces the potential for human error, thus leading to fewer defects and rework. With advancements in robotics and artificial intelligence, robotic arc welding systems are becoming smarter and more capable, allowing for complex welds that were once difficult to achieve manually.

As we delve into the top ten benefits of robotic arc welding, it becomes clear that this technology is not just an option for modern manufacturing, but a necessity for those looking to remain competitive in a global market. From improving operational efficiency to ensuring worker safety, robotic arc welding is paving the way for the future of industry, heralding a new era of innovation and excellence in manufacturing processes.

Advantages of Automation in Robotic Arc Welding

Robotic arc welding has revolutionized modern manufacturing, offering a host of advantages that enhance productivity and quality. One of the key benefits of automation in this field is the consistent precision it provides. Unlike manual welding, robotic systems can maintain exact parameters throughout the welding process, ensuring uniformity in weld quality and reducing the risk of defects. This high level of precision translates to less material waste and fewer rework requirements, ultimately saving time and resources.

Additionally, the integration of robotic arc welding systems allows for greater flexibility in manufacturing operations. Robots can be programmed to execute various welding tasks, accommodating different shapes, sizes, and materials with ease. This flexibility supports rapid production changes, enabling manufacturers to respond quickly to market demands and customize products without significant downtime.

Tips: When implementing robotic arc welding in your facility, it’s essential to invest time in training staff on how to operate and maintain the robots. Regular maintenance schedules can also prolong the lifespan of the equipment, ensuring sustained performance. Furthermore, conducting periodic assessments of the welding parameters can help in optimizing operations for improved quality and efficiency, making the most of your robotic systems.

Top 10 Benefits of Robotic Arc Welding for Modern Manufacturing

Enhanced Precision and Consistency in Welding Production

The advent of robotic arc welding has revolutionized modern manufacturing, offering enhanced precision and consistency in welding production. The systematic approach of robotic systems ensures that each weld is executed with the same level of accuracy, minimizing variables that could affect the quality of the final product. This consistency is critical in applications where structural integrity and reliability are paramount, allowing manufacturers to meet stringent quality standards while reducing the risk of defects.

To maximize the benefits of robotic arc welding, manufacturers should invest in proper programming and operational training. It's essential to understand the specific requirements of different materials and the best practices for setting parameters such as voltage and speed. Regular maintenance of the robotic systems is also crucial; by keeping equipment in optimal condition, companies ensure that precision levels remain high over time, minimizing the likelihood of errors in production.

Moreover, integrating smart technology solutions can enhance the overall welding process. Utilizing real-time monitoring systems allows for immediate adjustments, ensuring that tolerances are consistently met throughout the welding sequence. This level of oversight not only boosts productivity but also reinforces the company's commitment to quality, fostering greater trust with clients who demand excellence in their manufactured goods.

Reduction of Labor Costs Through Robotic Systems

Robotic arc welding has emerged as a transformative force in modern manufacturing, particularly regarding cost efficiency. The implementation of robotic systems in welding processes allows manufacturers to significantly reduce labor costs. According to a report by the International Federation of Robotics, companies adopting automation can decrease labor expenses by as much as 30%, leading to substantial savings over time. These reductions stem from decreased reliance on manual labor, minimized downtime, and increased production speeds, which enhance overall operational efficiency.

Additionally, robotic arc welding enhances precision, resulting in fewer defects and waste. A study by the American Welding Society highlights that automated welding can improve weld quality by up to 40%, subsequently reducing rework and associated costs. This level of accuracy ensures that manufacturers not only save on labor but also optimize material usage, further decreasing expenses.

Tips: To maximize the benefits of robotic welding, companies should consider implementing regular training for their staff to understand and manage these systems effectively. Furthermore, investing in predictive maintenance can prevent unanticipated breakdowns, keeping labor costs low and productivity high. By embracing these strategies, businesses can ensure they fully capitalize on the economic advantages offered by robotic welding technologies.

Improved Safety and Risk Management in Welding Environments

The improvement of safety and risk management in welding environments is one of the most significant advantages of adopting robotic arc welding technology. Traditional welding methods often expose workers to various hazards, including harmful fumes, intense heat, and the risk of accidents from operating heavy machinery. By integrating robotic systems into the workflow, manufacturers can significantly reduce these dangers. Robots can perform tasks in high-risk areas, minimizing human exposure to potentially harmful conditions and thereby enhancing workplace safety.

Moreover, robotic arc welding systems come equipped with advanced sensors and monitoring technologies that can detect anomalies and operational inefficiencies. This not only helps in maintaining consistent weld quality but also plays a crucial role in risk mitigation. By ensuring the equipment operates within safe parameters, manufacturers can prevent accidents before they occur. Additionally, the automation of repetitive welding tasks decreases the likelihood of human error, which is a common factor in workplace injuries. As a result, companies can foster a safer work environment while also increasing overall productivity and efficiency.

Top 10 Benefits of Robotic Arc Welding for Modern Manufacturing

| Benefit | Description | Impact on Safety |

|---|---|---|

| Increased Precision | Robotic arc welding offers higher precision than manual methods, leading to reduced material waste and improved final product quality. | Minimized risk of human error, which can lead to accidents. |

| Enhanced Productivity | Robots can operate continuously without breaks, significantly increasing throughput. | Reduced worker fatigue and potential for accidents due to repetitive tasks. |

| Improved Working Conditions | Automatic processes keep operators away from hazardous environments, reducing exposure to harmful fumes and heat. | Safer workplace, reducing health risks and associated liabilities. |

| Consistency in Quality | Robots ensure uniform welds, maintaining quality standards across all outputs. | Less variability in production, leading to fewer defects and rework incidents. |

| Lower Labor Costs | Reduces the number of welders needed on-site, allowing reallocation of labor resources. | Decreased risks associated with high labor turnover and training requirements. |

| Flexibility and Adaptability | Robots can be programmed to perform various welding tasks, adapting to changes in production needs. | Easier transitions when changing product lines, reducing downtime risks. |

| Data Collection and Analysis | Robots equipped with sensors collect data for analysis, improving the understanding of welding processes. | Better monitoring leads to proactive maintenance and preventive safety measures. |

| Space Efficiency | Compact robotic systems occupy less space than traditional welding setups. | More efficient use of workspace, leading to better traffic flow and reduced accident potential. |

| Reduced Heat Affected Zones | Robotic welding techniques can minimize the heat affected zones, leading to lower distortion in parts. | Less distortion reduces the risk of structural vulnerabilities in welded components. |

| Improved Collaboration | Robots can seamlessly integrate into existing workflows, enhancing collaboration between human workers and machines. | Smoother workflows reduce confusion and the likelihood of workplace accidents. |

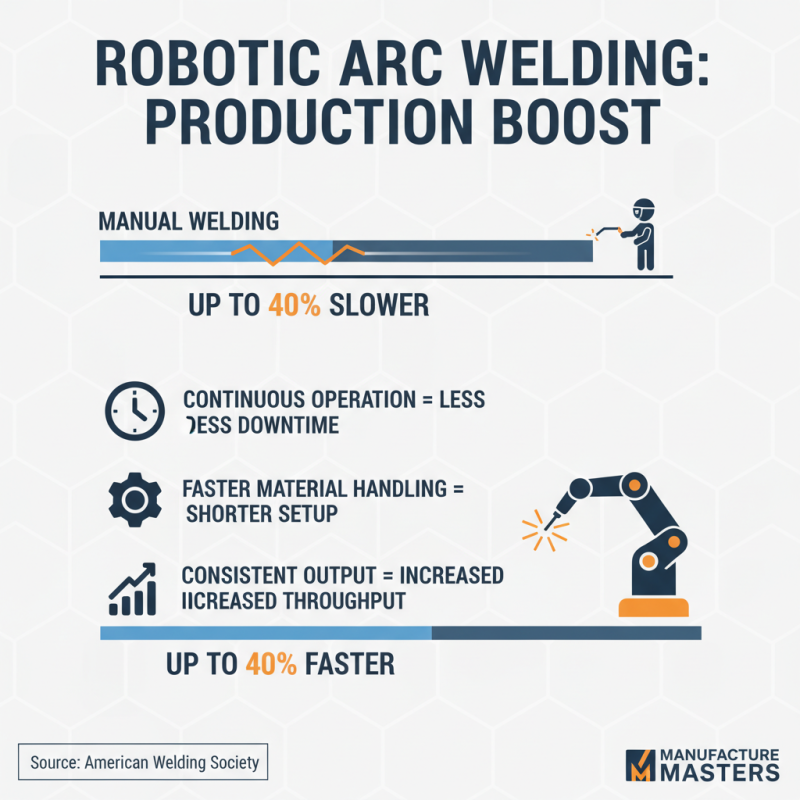

Increased Production Speed and Efficiency in Manufacturing Processes

Robotic arc welding has emerged as a pivotal technology in modern manufacturing, significantly enhancing production speed and efficiency. According to the American Welding Society, the implementation of robotic welding systems can boost production rates by up to 40% compared to traditional manual welding methods. This increase is largely due to the reduced downtime associated with robots, which can operate continuously without fatigue, maintaining consistent output throughout long production runs. Furthermore, automation allows for faster material handling and shorter setup times, which are critical in meeting tight production schedules and increasing overall throughput.

Another key advantage of robotic arc welding lies in its ability to improve process consistency and quality. Reports from the International Journal of Advanced Manufacturing Technology indicate that automated welding processes can achieve a defect rate that is 50-70% lower than manual techniques. This reduction in variability ensures that products meet stringent quality standards, which is essential for manufacturers aiming to minimize rework and waste. By integrating robotic systems, manufacturers can streamline their workflows, thus enhancing productivity while ensuring that output quality remains high, ultimately leading to higher customer satisfaction and increased competitiveness in the market.

Related Posts

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

7 Best 3D Vision Systems for Robots: Enhance Automation & Efficiency

-

Top Robotic Vision Technologies Transforming Industries Today

-

Top 5 Benefits of Robotic Process Automation for Modern Businesses

-

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

-

Exploring the Future of Robot Servos at the 138th China Import and Export Fair in 2025