How to Choose the Best Inspection Robot for Your Needs?

Choosing the right inspection robot can be challenging. Many factors come into play. You might find yourself overwhelmed by options. Different environments require different capabilities.

An inspection robot can perform various tasks. It can be used in industrial settings, infrastructure inspections, and even in healthcare. Each application demands specific features. Some robots excel in tight spaces, while others have advanced imaging technology. Understanding what you need is essential.

Consider your budget and the robot's technical specifications. Performance, durability, and ease of use matter greatly. It's crucial to reflect on your unique requirements. You might realize that the most expensive robot isn't always the best fit. Before making a decision, ask yourself if it meets all your criteria.

Understanding the Different Types of Inspection Robots Available

When it comes to inspection robots, understanding the different types is crucial. There are several categories, each designed for specific environments and tasks. For instance, aerial drones are great for large outdoor inspections. They can cover vast areas quickly. Ground-based robots, on the other hand, excel in tight spaces. They navigate traditionally inaccessible areas, making them valuable in industrial settings.

In addition, some inspection robots are equipped with specialized sensors. These can detect leaks, measure temperature, or even assess structural integrity. However, not all robots are created equal. Some may struggle with complex terrains or in the presence of adverse weather conditions. It's essential to reflect on your specific needs. Do you require high mobility or advanced sensing capabilities?

Consider also the robot's operating time. Many affordable options might have limited battery life, compromising efficiency. A machine that doesn’t operate long enough can lead to increased downtime. Finding the right balance between functionality and reliability is vital. Ultimately, investing time in research can help avoid costly mistakes. Choosing the right inspection robot depends not just on features but on understanding your environment and requirements.

Identifying Your Specific Inspection Needs and Requirements

When choosing an inspection robot, start by identifying your specific needs. Think about the environment where the robot will operate. Is it a factory, a construction site, or an underground tunnel? Each scenario requires different features.

Not all robots are suited for every space. Consider the types of inspections needed. Do you require visual inspections, thermal imaging, or gas detection? Each function comes with its own requirements. A robot may excel in one type but fall short in another. Ensure the robot you select can perform all required tasks effectively.

Tips: Evaluate the robot's size and mobility. It should fit through tight spaces. Also, check its battery life. Some models die quickly in demanding environments. A robot with poor battery performance can slow down your operations. The cost is important too. Higher price tags don't always equal better quality. Reflect on your budget before making a decision.

Evaluating the Key Features of Inspection Robots

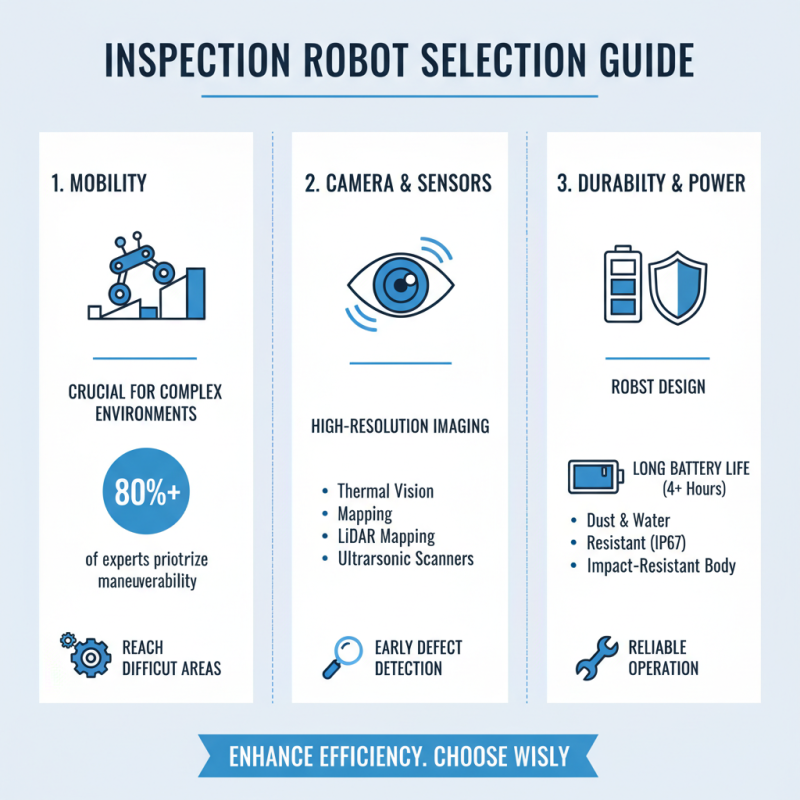

When selecting an inspection robot, evaluating key features is crucial. The right robot enhances efficiency during inspections. For instance, mobility is vital. Over 80% of survey respondents emphasize the need for robots that can navigate complex environments. Choose a model with superior maneuverability. This ensures it can reach difficult areas.

Camera quality is another important factor. A study indicates that high-resolution cameras lead to 30% more accurate defect detection. Inspectors rely on clear visuals. Look for robots equipped with advanced imaging technology. This helps in capturing details that may go unnoticed.

Battery life cannot be overlooked. Robots with longer operational times reduce downtime. Approximately 65% of industry experts recommend a minimum battery life of four hours for extensive inspections. Short battery life limits productivity. Some designs may fall short. Always evaluate usage needs before making a decision. This reflection can guide the selection process.

Comparing Costs and Budgeting for Your Inspection Robot

When budgeting for an inspection robot, cost is a major factor. Prices can vary significantly based on features and capabilities. Standard models often cost less, but they may lack advanced functionalities. Think about your specific needs before making a choice. Does your operation require high-resolution cameras or advanced scanning options? If so, be prepared to invest more.

It’s also important to consider ongoing costs. Maintenance and training can add to your budget. Some robots need regular software updates. Worker training is crucial to maximize efficiency. These costs may influence your initial budget decisions. Always set aside extra funds for unforeseen expenses. Managing a budget is an ongoing process, not just a one-time task.

Reflect on your requirements carefully. Are you prioritizing long-term savings or initial affordability? Sometimes, spending more upfront can save costs over time. Keep track of your operational needs. It will help in evaluating your options realistically. The best choice isn’t always the most expensive or the cheapest. Take your time to evaluate what truly works for you.

Comparing Costs of Different Inspection Robots

Assessing Maintenance and Support Options for Long-Term Use

When selecting an inspection robot, maintenance and support are critical. Reliable support can influence the overall effectiveness of your operations. Understand the maintenance needs of the robot. Some models require regular software updates. Others may need physical inspections after specific intervals. Assessing these requirements ensures the robot performs consistently.

Evaluate the available support options carefully. Effective customer support can save time and resources. Determine if the supplier offers training programs. These can improve your team's proficiency with the robot. A good support system should also include access to repair services. Long response times can be frustrating. Consider how quickly the provider can address issues.

Lastly, think about documentation and resources. User manuals should be clear and accessible. Online forums and FAQs can assist with common problems. However, not all providers have comprehensive resources. Reflect on your specific requirements, and ensure you choose wisely. A robot with strong support options can significantly impact its long-term utility.

Related Posts

-

How to Choose the Right Inspection Robot for Your Industry Needs

-

10 Essential Tips for Servo Robot Seam Tracking Success

-

Top 10 Tips for Choosing the Right Inspection Robot for Your Industry

-

Why Is Seam Tracking Welding Essential for Precision in Modern Manufacturing?

-

Why Robot Software is Essential for Modern Business Efficiency

-

What is Robotic Vision? Understanding Its Importance and Applications in Automation