2026 How to Choose the Best Welding Robot for Your Business Needs?

Choosing the best welding robot for your business can be challenging. The right equipment can boost productivity and improve quality. However, not all welding robots are created equal. A poor choice can lead to frustration and wasted resources.

When evaluating welding robots, consider your specific needs. What types of materials will you work with? How complex are the welding tasks? A versatile robot can adapt to different projects, but it may require a larger initial investment. Reflect on your budget versus capability needs.

Furthermore, after purchase, some businesses realize that training is essential. An advanced welding robot might be difficult for staff to operate without proper guidance. Investing in training is as crucial as selecting the right machine. Balancing your choices can lead to long-term success and efficiency in your operations.

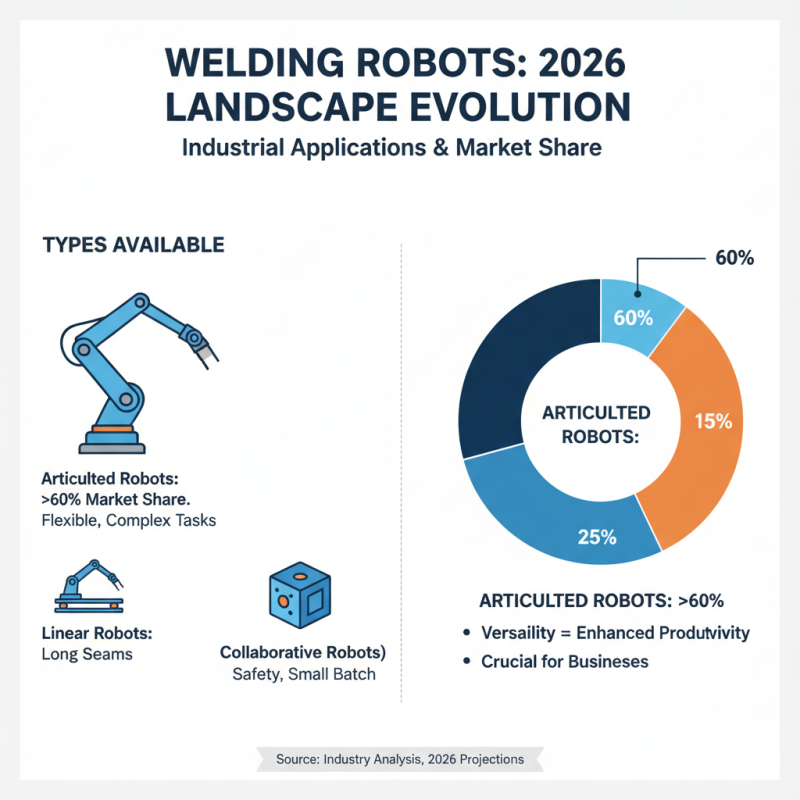

Understanding the Different Types of Welding Robots Available in 2026

The landscape of welding robots has evolved significantly by 2026. Various types are available, catering to different industrial needs. Articulated robots dominate the market, accounting for over 60% of all welding applications. Their flexibility allows them to perform complex tasks. This versatility is crucial for businesses looking to enhance productivity.

Another popular type is the collaborative robot, or cobot. These robots work alongside human operators without the need for safety cages. They are ideal for small-scale operations and can increase efficiency by up to 30%, according to recent industry studies. However, their payload capacity is often less than traditional robots, which can be a limiting factor.

Plasma and laser welding robots are gaining traction for precision welding tasks. They offer highly focused energy, capable of handling intricate projects. Despite these advantages, businesses must consider their high initial costs and maintenance needs. Choosing the right welding robot involves assessing specific requirements and costs. It's important to weigh the pros and cons of each type carefully.

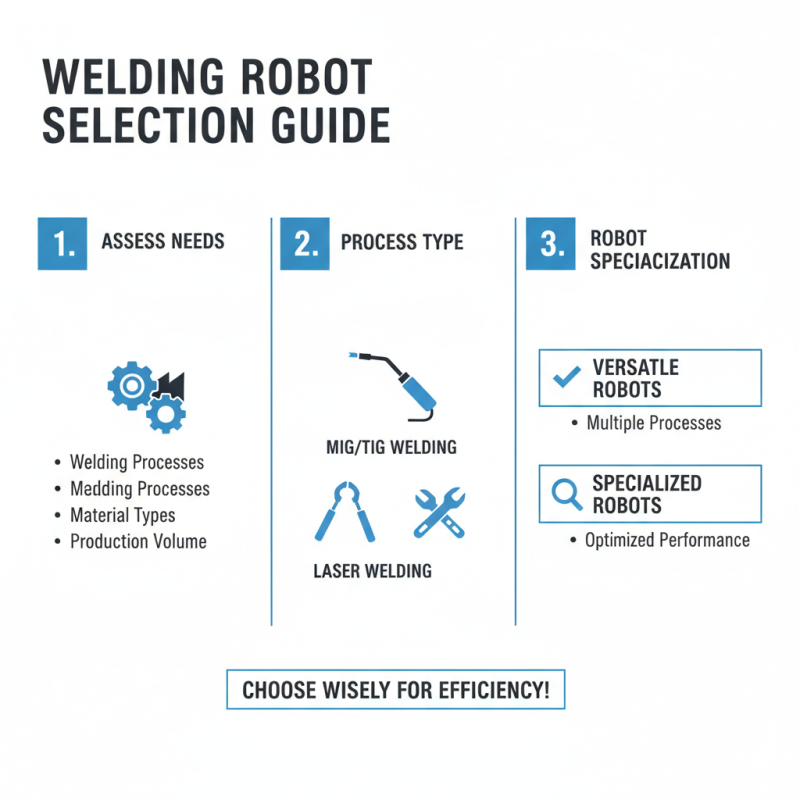

Evaluating Your Business's Specific Welding Requirements and Capabilities

When selecting a welding robot, evaluating your business's specific needs is crucial. Start by assessing the types of welding processes you frequently use. Are you mainly performing MIG, TIG, or spot welding? Understanding these details will guide you in choosing the right robot. While some robots are versatile, others are specialized. A specialized robot may offer better performance in a specific type of welding.

Next, consider the size and scale of your projects. If your business deals with large components, you’ll need a robot with a longer reach. Conversely, for smaller items, a more compact machine may suffice. It's essential to reflect on the volume of work too. Higher production rates may demand a faster robot. Think about the layout of your workspace as well. Space constraints can impact your choice significantly.

Finally, don't overlook the integration aspect. Ensure the robot will work seamlessly with your existing systems. Sometimes, companies rush into purchasing, only to find compatibility issues later. Take time to analyze your workforce's skills too. A robot that is too advanced may be underutilized if your team cannot operate it effectively. These reflections will help make a well-informed choice that aligns with your business’s goals.

Key Features and Specifications to Look for in a Welding Robot

When selecting a welding robot, understanding key features is essential. Pay close attention to the robot’s payload capacity. Robots should handle the weight of the welding equipment and workpieces with ease. According to a study by the International Federation of Robotics, payload capacity is crucial for optimizing efficiency in welding tasks. Look for robots with at least a 5 kg payload for general applications.

Next, consider the robot's reach. A greater reach means more flexibility in the workspace. Robots with a reach of around 1.5 to 2 meters generally cover a larger area without needing to reposition. This can significantly reduce downtime. As reported by the American Welding Society, a versatile reach also enhances precision during operation.

Software compatibility should not be overlooked. The ability to integrate advanced programming and simulation software is vital. Reports indicate that modern welding robots with intuitive interfaces can reduce training time by 30%. This is beneficial when adapting to different welding tasks. Nonetheless, ensure the software aligns with your specific processes. Not all solutions are perfect. Sometimes, companies may find that acquired systems do not meet evolving needs. It's essential to assess future requirements when making your choice.

Welding Robot Specification Comparison

Analyzing Cost-Effectiveness and ROI of Welding Robot Investment

Investing in a welding robot can seem daunting for many businesses. The initial cost can be high. However, understanding the cost-effectiveness and potential return on investment (ROI) is crucial. A skilled robot can operate faster than human welders. It can often work 24/7 without breaks. This increased efficiency can significantly lower production costs over time.

It’s essential to analyze your specific needs. Consider the types of projects your business handles. Not every robot will suit every application. Some might struggle with complex joints or materials. These factors can impact overall performance and ROI. Think about potential downtime for issues that could arise. A cheap robot might end up costing more in repairs and lost productivity.

Evaluate the long-term benefits carefully. While the upfront investment is significant, savings on labor and enhanced quality can create a strong case for ROI. However, think critically about your decision. Will your investment truly meet your needs? Take the time to assess all elements before proceeding.

Future Trends in Welding Robotics: What to Expect by 2026

As welding technology advances, the landscape of welding robotics is evolving. Predictions suggest that by 2026, the global welding robot market could grow by over 20%. This growth is largely driven by industries like automotive and construction, which seek greater efficiency. Robots can work faster and produce high-quality welds, reducing the risk of human error.

Tips: Consider your specific needs. What materials will you be welding? Ensure the robot you choose can handle those. If you're focusing on small batches, a flexible robotic arm may be ideal.

The focus on Industry 4.0 means more integration with smart technologies. Anticipate increased connectivity in welding robots, allowing for real-time monitoring. However, navigating this technology can be overwhelming. Not all businesses will adapt at the same pace.

Tips: Invest in training for your staff. A well-trained team can maximize the benefits of new robotic systems. Evaluate the total cost of ownership to avoid unexpected expenses. Think carefully about your business's long-term needs. What might be essential today could evolve.

2026 How to Choose the Best Welding Robot for Your Business Needs?

| Feature | Value |

|---|---|

| Payload Capacity | 50-300 kg |

| Operating Range | 1500 mm - 3000 mm |

| Precision | ±0.05 mm |

| Speed | 2.5 m/s |

| Training Ease | User-friendly Interface |

| Integration Capabilities | Compatible with CAD/CAM Software |

| Maintenance Frequency | Every 6 Months |

| Expected Lifespan | 10-15 Years |

Related Posts

-

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

-

Top 2025 Welding Robots: Innovations Transforming the Industry

-

Why Is Seam Tracking Welding Essential for Precision in Modern Manufacturing?

-

Top 10 Benefits of Robotic Arc Welding for Modern Manufacturing

-

Top 10 Benefits of 3D Vision Systems for Robots?

-

Unlocking the Future of Automation with Revolutionary Robot Software