How to Choose the Right Dispensing Robot for Your Business Needs?

In today’s fast-paced manufacturing landscape, the need for efficiency is paramount. Businesses increasingly adopt automation to meet rising demands. A recent report by MarketsandMarkets indicates that the dispensing robot market is expected to reach $5.4 billion by 2025, growing at a CAGR of 12.8%. This statistic exemplifies the pivotal role dispensing robots play in enhancing productivity.

Selecting the right dispensing robot for business needs requires thoughtful consideration. Factors include the type of materials being handled and the desired level of precision. Not every robot is suited for every task. Misjudgments can lead to operational inefficiencies or increased costs. It's essential to reflect on specific requirements and existing processes before choosing.

Moreover, the integration of a dispensing robot can be complex. Companies often face challenges during implementation. Training staff and adjusting workflows are common hurdles. These reflections highlight the importance of carefully evaluating options. Addressing these issues proactively can ensure smoother transitions and better outcomes.

Understanding the Basics of Dispensing Robots and Their Applications

Dispensing robots have transformed various industries by automating repetitive tasks. They are designed to handle fluids, powders, and other materials with precision. Common applications include manufacturing, food production, and pharmaceutical dispensing.

These robots improve efficiency and reduce waste, making business operations smoother.

Understanding how dispensing robots work is crucial. They typically use advanced sensors and software to ensure accurate dispensing. Some robots may struggle with thicker materials or varying temperatures.

This requires businesses to assess their specific needs carefully. Not every robot will meet every requirement.

Therefore, trial tests can provide insights into their effectiveness in real-world applications.

Businesses must also consider maintenance and possible downtimes. Some robots might require regular recalibration or component replacements.

Evaluating Your Business Needs and Objectives for Automation

When thinking about automation, consider your specific business needs and objectives. Start by analyzing your current operations. What tasks are repetitive and time-consuming? Identifying these areas helps pinpoint where a dispensing robot can add value. For example, if packaging is slow, a robot could speed up that process.

Next, think about your goals. Are you looking to increase efficiency or reduce human error? Understanding your priorities influences your choice of robot. You may need a machine that can handle delicate items if your products are fragile. However, if speed is crucial, focus on high-capacity options. Reflect on the scalability of your needs as well. Can your chosen robot grow with your business?

It’s essential to evaluate your budget too. Robotics can be an investment. What is the return on investment you expect? Sometimes, the cheapest option may lack the features you need. Ultimately, research is vital. Sometimes, what seems perfect on paper may not work in practice. Gather feedback from industry experts to inform your decision. Balancing needs with available technology is key.

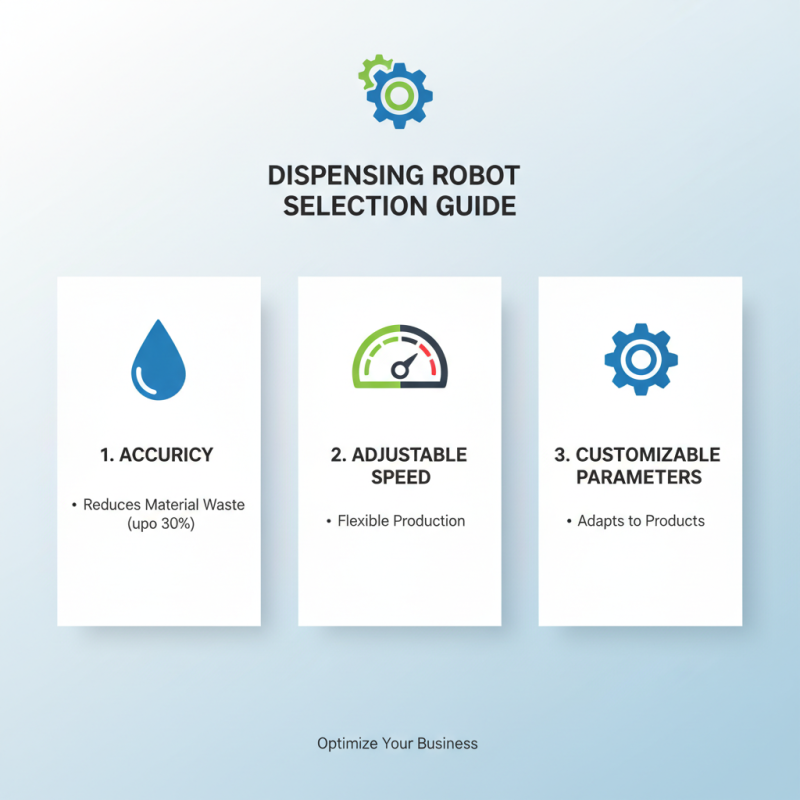

Key Features to Consider When Selecting a Dispensing Robot

When selecting a dispensing robot, consider key features that align with your business needs. One crucial aspect is the accuracy of the robot. In a recent industry report, it was noted that high-precision dispensing can reduce material waste by up to 30%. Look for robots that offer adjustable dispensing speeds and customizable parameters. These allow for flexibility in production, catering to different product types.

Another important factor is the ease of integration. Robots that support standard communication protocols can seamlessly connect with existing systems. Complex setups can hinder workflow and slow production. Simplicity is vital in maintaining efficiency. Moreover, assess the robot’s maintenance requirements. Advanced models can reduce downtime with predictive maintenance alerts. This can enhance overall productivity but demands an upfront investment.

Finally, consider the scalability of the robot. Many businesses overlook this aspect, focusing solely on immediate needs. As production scales, a robot's capability to adapt becomes essential. An Infotech report indicated that 70% of businesses saw growth in output by upgrading to scalable automation solutions. Reflect on how your needs may evolve.

Comparing Different Types of Dispensing Robots on the Market

When selecting a dispensing robot, it's crucial to compare the available types. The market offers various models suited for different applications. Each type has unique features and capabilities. Some robots are programmed for precise liquid dispensing. Others excel in solid materials. Understanding these options is vital for making an informed choice.

Consider the application first. If speed is your priority, a high-speed model may be best. However, this often sacrifices some accuracy. On the other hand, precision-focused robots may operate slower but ensure better consistency. It's a balancing act. Additionally, evaluate payload capacity. Some robots can handle heavier materials, but they may be bulkier. Space can be a limiting factor in many facilities.

Furthermore, ease of use is another aspect to think about. Some robots come with intuitive interfaces. Others require extensive training to operate effectively. This learning curve can become a hidden cost. Don't forget about maintenance requirements. More complex models might demand more frequent service. These factors should all weigh into your decision-making process.

Comparison of Different Types of Dispensing Robots

Budgeting for Your Dispensing Robot: Cost Considerations and ROI

When budgeting for a dispensing robot, consider the initial cost. Robots vary widely in price. Many factors influence this, including technology and features. A high price doesn’t always mean better performance. Assess what features your business truly needs. Have a list ready before shopping.

Think about long-term ROI. Calculate how much time and cost savings the robot can deliver. If a robot reduces labor costs, it may pay for itself quickly. However, maintenance expenses can add up. Regular maintenance is necessary to keep systems running smoothly.

Tips: Always factor in unexpected costs. Have a buffer in your budget for repairs and software updates. Research the average lifespan of the robot. This can help project your long-term investment. Engage with users online to gain insights into their experiences. Keep an eye out for financing options. Sometimes, leasing can make initial costs more manageable.

Related Posts

-

7 Best 3D Vision Systems for Robots: Enhance Automation & Efficiency

-

Top Robotic Vision Technologies Transforming Industries Today

-

How to Leverage Robotic Vision for Enhanced Automation in 2025

-

The Future of Healthcare Automation How Dispensing Robots Are Revolutionizing Patient Care

-

Unlocking the Future of Automation with Digital Robotic Process Techniques

-

Exploring the Future of Robot Servo Technology at the 2025 China Import and Export Fair