Top 10 Tips for Choosing the Right Inspection Robot for Your Industry

In today's rapidly advancing technological landscape, inspection robots have emerged as invaluable tools across various industries. These automated machines are designed to perform intricate inspections, enhancing safety, efficiency, and accuracy in operations that were once time-consuming and labor-intensive. However, with a diverse range of inspection robots available, selecting the right one for your specific needs can be daunting. This decision is critical, as the effectiveness of an inspection robot can significantly impact overall productivity and operational success.

When considering an inspection robot, it is essential to evaluate factors such as compatibility with existing systems, the specific requirements of your industry, and the robot's capabilities in navigating challenging environments. Furthermore, understanding the technological advancements in inspection robotics, including features like real-time data analysis and autonomous navigation, can help you make an informed choice. In this guide, we will explore the top ten tips for choosing the right inspection robot tailored to your industry, ensuring that you invest in a solution that meets your unique demands while maximizing the potential benefits of robotic technology.

Understanding the Role of Inspection Robots in Various Industries

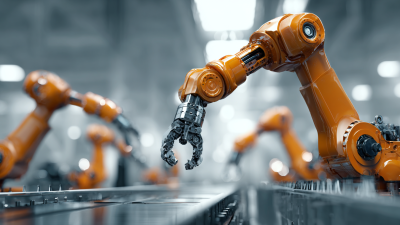

In an era where automation and technology are revolutionizing industries, inspection robots have emerged as critical tools for enhancing operational efficiency and ensuring safety. These robots play a vital role in sectors such as manufacturing, construction, and oil and gas, where precise inspection is crucial to prevent costly downtimes and accidents. By deploying robotic systems, industries can execute routine checks in hazardous environments or locations that are difficult to access, thereby reducing human risk and increasing inspection accuracy.

The integration of inspection robots can also lead to significant cost savings and productivity gains. For instance, in manufacturing, robots equipped with advanced imaging and sensing technology can swiftly identify defects in products on the assembly line, ensuring that quality standards are upheld without slowing down production. Similarly, in infrastructure, inspection drones can assess the condition of bridges and buildings, allowing for timely maintenance that prolongs the lifespan of these structures. As industries continue to embrace automation, understanding the specific roles and capabilities of inspection robots is essential for selecting the right model to meet diverse operational needs.

Key Features to Look for in Inspection Robots

When selecting an inspection robot for your industry, it’s essential to concentrate on the key features that align with your specific needs. First and foremost, consider the robot's mobility and versatility.

The right inspection robot should be able to navigate various terrains and environments, whether it's indoors in a manufacturing facility or outdoors in harsh weather conditions. Look for robots equipped with advanced navigation systems, including real-time mapping and obstacle avoidance capabilities, which allow them to operate efficiently without extensive human intervention.

Another critical feature is the data collection and analysis capabilities of the inspection robot. Ensure it is equipped with high-quality cameras and sensors that can capture detailed images and analytics for thorough inspections.

Robots with advanced imaging technology, such as thermal or infrared sensors, can detect issues often invisible to the naked eye, providing a more comprehensive overview of the inspected area. Additionally, consider the robot's integration with existing systems, as real-time data sharing and reporting tools can enhance the efficiency and efficacy of inspection processes, enabling quick decision-making based on accurate information.

Assessing the Environmental Conditions for Robot Operation

When selecting an inspection robot for your industry, one of the most crucial factors to consider is the environmental conditions in which the robot will operate. Different environments, whether they are industrial, hazardous, or confined spaces, present unique challenges that can significantly affect the choice of robot. For instance, robots designed for harsh environments must have robust protective features to withstand extreme temperatures, humidity, or corrosive chemicals. These factors will directly influence not only the robot's operational capabilities but also its long-term maintenance and reliability.

Moreover, terrain is another vital aspect of environmental assessment. Inspection robots intended for outdoor use may require specialized navigation systems to handle uneven or rugged surfaces effectively. In contrast, robots operating in indoor environments might prioritize compact design and advanced mobility to maneuver through tight spaces. Additionally, considerations around power supply and connectivity are essential, as some environments may face challenges such as limited access to power sources or unstable communications. By thoroughly evaluating these environmental conditions, businesses can ensure they select an inspection robot that is well-suited to their operational landscape, ultimately enhancing efficiency and safety.

Top 10 Tips for Choosing the Right Inspection Robot for Your Industry - Assessing the Environmental Conditions for Robot Operation

| Criteria | Recommendation | Environmental Conditions | Examples of Suitable Robots |

|---|---|---|---|

| Temperature Resistance | Choose robots that can operate in extreme temperatures | -20°C to 50°C | Robot A, Robot B |

| Moisture Resistance | Select waterproof models for humid environments | High humidity areas, rain exposure | Robot C, Robot D |

| Dust and Particulate Resistance | Look for dustproof designs for industrial settings | Dusty environments | Robot E, Robot F |

| Mobility Type | Consider tracked or wheeled options depending on terrain | Rugged terrain, smooth surfaces | Robot G, Robot H |

| Battery Life | Evaluate the battery capacity for long inspections | Hours of operation needed | Robot I, Robot J |

| Sensor Types | Ensure the robot has appropriate sensors for the task | Visual, thermal, ultrasonic | Robot K, Robot L |

| Weight Limitations | Consider the weight the robot can safely carry | Weight of tools/equipment | Robot M, Robot N |

| Communication Protocols | Ensure compatibility with existing systems | Wireless, Ethernet options | Robot O, Robot P |

| Maintenance Requirements | Assess ease of maintenance and parts availability | Maintenance schedules, parts service | Robot Q, Robot R |

| Cost of Ownership | Analyze overall costs including purchase, operation, and maintenance | Total cost of ownership | Robot S, Robot T |

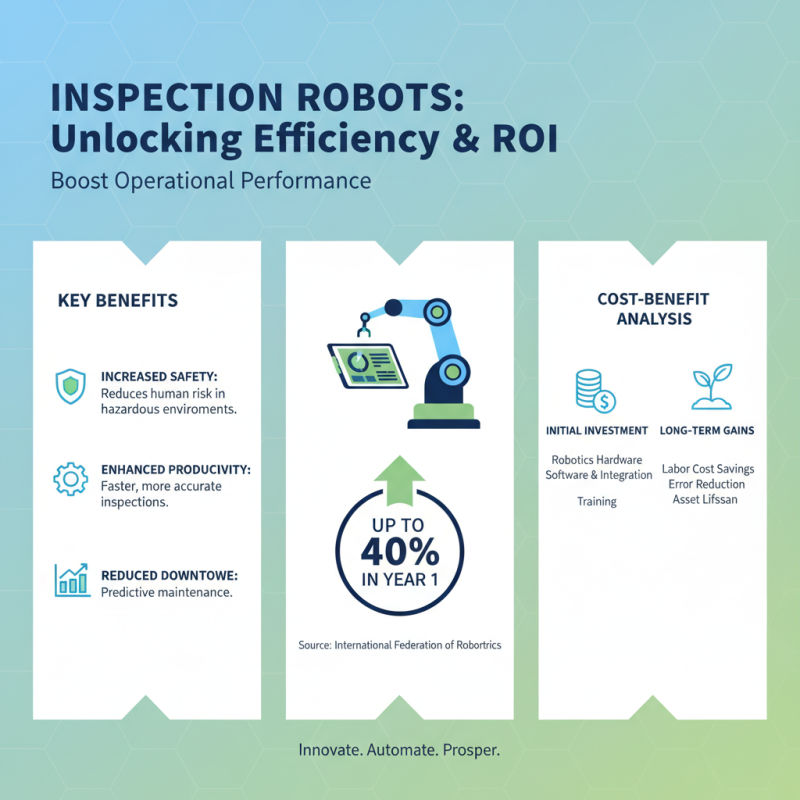

Evaluating the Cost-Benefit Ratio of Inspection Robot Investment

Investing in inspection robots can significantly enhance operational efficiency across various industries. When evaluating the cost-benefit ratio of such an investment, it is vital to consider both the initial expenditures and the long-term gains that can result from increased safety and productivity. A report by the International Federation of Robotics indicates that companies using automation technologies like inspection robots can experience a return on investment (ROI) of up to 40% within the first year of implementation. This impressive figure highlights the potential savings in labor costs and the reduction in downtime that robotic inspections can offer.

Moreover, the ongoing maintenance and inspection tasks can lead to substantial risk management benefits. According to industry analyses, organizations that utilize robotic solutions report up to 50% fewer safety incidents due to improved inspection accuracy and consistency. This translates not only into lower insurance premiums but also boosts overall employee morale and productivity. Additionally, the enhanced data collection capacities of inspection robots facilitate better decision-making, leading to further financial advantages over time. Therefore, industries focused on safety, compliance, and efficiency should carefully weigh these potential benefits against the upfront costs to fully understand the lucrative prospects of integrating inspection robots into their operations.

Ensuring Compliance with Industry Standards and Regulations

When selecting the appropriate inspection robot for your industry, ensuring compliance with industry standards and regulations is paramount. Various sectors, such as manufacturing, construction, and food safety, are governed by strict frameworks that dictate the quality and safety of operations. According to a report by the International Organization for Standardization (ISO), over 1.5 million organizations worldwide are ISO-certified, reflecting the necessity of adhering to these standards to maintain operational integrity. An inspection robot must meet such compliance requirements, ensuring it can thoroughly adhere to guidelines stipulated by regulatory bodies.

Furthermore, automation technologies, including inspection robots, have become vital in facilitating compliance processes. The latest market research by Grand View Research indicates that the global inspection robot market is expected to reach USD 10.5 billion by 2027, driven by the increasing demand for enhanced safety protocols and regulatory adherence. For industries like pharmaceuticals and food processing that are subject to rigorous compliance audits, selecting inspection robots that not only fulfill specific technological requirements but are also compliant with FDA regulations and the Hazard Analysis Critical Control Point (HACCP) principles is essential. Investing in robots equipped with advanced sensors and data collection capabilities can significantly streamline regulatory compliance and reduce the risk of non-compliance penalties.

Related Posts

-

How to Choose the Right Inspection Robot for Your Industry Needs

-

Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

-

The Future of Healthcare Automation How Dispensing Robots Are Revolutionizing Patient Care

-

Unlocking the Future of Automation with Advanced Robot Vision Systems

-

Robotic Process Innovations at the 138th Canton Fair 2025 Transforming Industry Standards in China

-

Unlocking the Future of Automation with Revolutionary Robot Software