What is a dispensing robot and how does it work?

A dispensing robot is a sophisticated machine designed to automate the process of dispensing various materials. These robots are commonly used in industries ranging from pharmaceuticals to manufacturing. By providing precise control, dispensing robots improve efficiency and accuracy. They can handle liquid, solid, or powder forms, ensuring consistency in output.

The technology behind a dispensing robot involves sensors, actuators, and software. Sensors monitor material levels, while actuators control the dispensing process. The robot's programming allows it to adapt to different materials and amounts. However, the complexity of these systems can lead to challenges. Malfunctions may occur, causing delays or incorrect dispensing.

Despite their advancements, dispensing robots are not infallible. They require regular maintenance and calibration to function optimally. Operators must stay vigilant to identify potential issues. This need for human oversight highlights an ongoing reliance on skilled personnel in automated environments. Dispensing robots represent a blend of innovation and imperfection, emphasizing the importance of continuous improvement.

What is a Dispensing Robot? Definition and Overview

A dispensing robot is an automated system designed for precise dispensing of various materials. These robots are commonly used in industries like pharmaceuticals, electronics, and food. By employing advanced sensors and precise control mechanisms, they offer consistent accuracy. According to a recent market report, the global dispensing robot market is expected to grow at a CAGR of 12% through 2027.

In many production environments, the implementation of dispensing robots reduces human error and increases efficiency. However, the cost of initial setup can be high. Companies should evaluate their production volume to determine if the investment makes sense. Simple adjustments and programming can lead to significant enhancements in performance over time.

Tips: When considering a dispensing robot, assess the layout of your workspace. Understand the limitations and capabilities of the robot selected. Trials and simulations can help in determining if the chosen solution meets your needs. Experimentation can reveal the areas in need of optimization. Relying solely on technology may not be sufficient; human oversight is still crucial for quality control.

Key Components and Technologies in Dispensing Robots

Dispensing robots are transforming various industries. These machines automate the process of delivering materials, medications, or goods. Key components play a vital role in their efficiency. The robotic arm is crucial; it mimics human movement. This arm must be precise to avoid errors.

Sensors aid the robot in identifying the correct items. They ensure accurate measurements and placement.

Another essential technology is the control system. It allows for programming and monitoring the robot’s actions in real-time. These systems can be complex. They often require specialized training to operate effectively. Integrating vision systems improves accuracy. Cameras help detect size and shape, reducing mistakes. However, programming can sometimes be overly intricate.

Robots also rely on power sources. Batteries or direct connections are common options. Battery life can limit operational time. Power issues can interrupt processes. Maintenance of these robots is necessary but often overlooked. Regular checks are essential for optimal performance. The balance between advanced technology and user-friendliness remains a challenge. Developing simple, efficient robots is a goal worth pursuing.

How Dispensing Robots Improve Efficiency in Pharmaceutical Settings

Dispensing robots play a crucial role in enhancing efficiency within pharmaceutical settings. These machines automate medication dispensing, leaving little room for human error. With precise dosing capabilities, they ensure that patients receive the correct medication in the right dosage. This precise automation decreases the risk of miscommunication among staff, which is common in busy pharmacies. Moreover, the ability to manage inventory increases workflow efficiency.

In addition to accuracy, dispensing robots can operate around the clock. They can handle repetitive tasks, freeing up pharmacists to focus on patient care. However, reliance on technology can sometimes lead to complacency. Staff may become overly dependent on robots, risking a decline in hands-on skills. It’s essential to maintain a balance between technology and human expertise. Robots should augment staff capabilities, not replace the critical thinking skills required in complex situations.

Implementing dispensing robots comes with challenges. Integration with existing systems can be complex and requires training. Staff must adapt to new methods of operation. This transition period may cause temporary dips in efficiency. Nevertheless, the long-term benefits of streamlined pharmacy operations usually outweigh initial hurdles. A thoughtful approach to implementation can ease this process, maximizing benefits while addressing potential drawbacks.

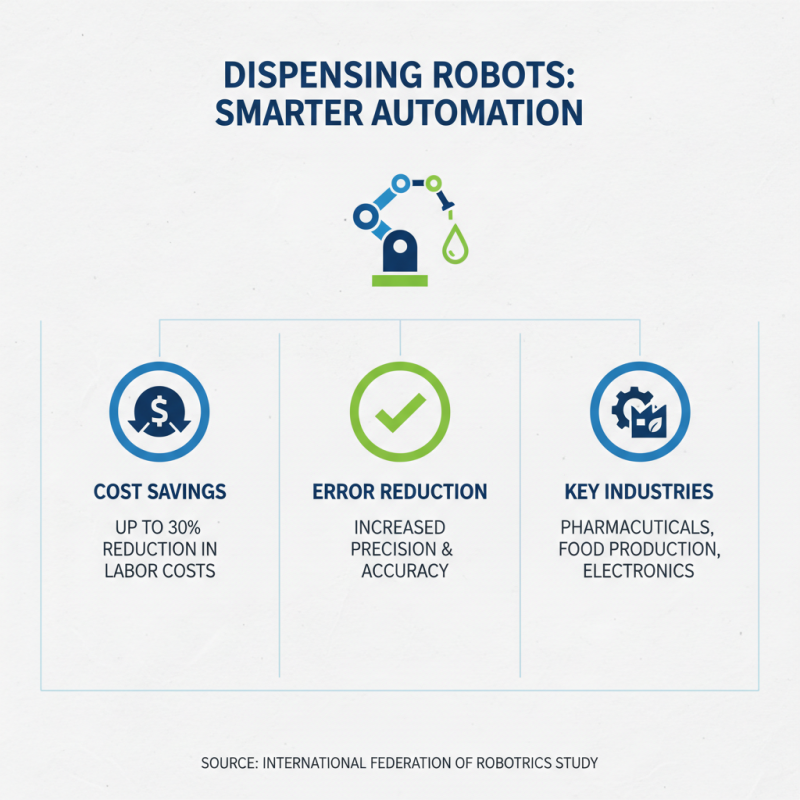

Statistical Impact: Cost Savings and Error Reduction with Robots

Dispensing robots have gained attention for their significant impact on cost savings and error reduction in various industries. According to a recent study by the International Federation of Robotics, automating dispensing processes can reduce labor costs by up to 30%. This is especially crucial in environments where precision is vital, such as pharmaceuticals and food production.

These robots excel at performing repetitive tasks with high accuracy. A report from the MIT Technology Review suggests that implementing dispensing robots can lower error rates by over 50%. However, it’s important to recognize that these systems are not infallible. Initial setup costs can be high, and staff must be trained to work alongside the technology. Errors can occur if the robots are not regularly maintained.

Despite these challenges, the return on investment can be substantial. Businesses often see a quick turnaround in savings. For example, a factory might save thousands in waste reductions alone. This reflects the potential for robots to transform operational efficiency. Yet companies must stay alert. Depending too heavily on automation can lead to skills degradation among workers. Balancing human skill and robotic precision is vital for success.

Future Trends: Advancements in Dispensing Robot Technologies

As dispensing robots evolve, new technologies reshape their capabilities. Advanced sensors allow for precise measurements. These robots can now handle various substances with remarkable accuracy. Increased automation reduces human error. It also improves efficiency in environments like pharmacies and laboratories.

AI technologies enhance their learning abilities. These machines analyze data to optimize dispensing processes over time. Still, there are challenges in integrating them fully into existing systems. Compatibility issues can hinder performance. Regular updates are necessary to maintain functionality and security.

User interface improvements are also vital. Simple designs ensure ease of use. However, some users may find these systems overwhelming at first. Training is essential to familiarize staff with technology. As demand grows, addressing these user experiences will be crucial for future advancements.

Related Posts

-

The Future of Healthcare Automation How Dispensing Robots Are Revolutionizing Patient Care

-

How to Enhance Your Photography Skills with Innovative Camera Robots

-

Exploring the Future of Robotic Process Automation for Business Efficiency

-

How to Choose the Right Dispensing Robot for Your Business Needs?

-

Why Use Robot Software for Your Business Success?

-

How to Use Robotic Vision for Enhanced Automation and Efficiency