10 Essential Tips for Effective Seam Tracking in Robotics

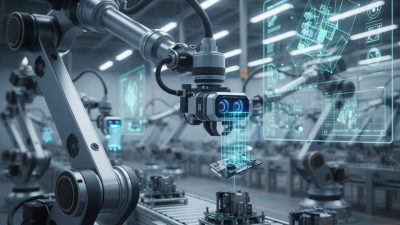

In the realm of robotics, seam tracking is crucial for ensuring precision in automated processes. This technique allows robots to accurately follow seams in various materials, enhancing manufacturing quality. Without effective seam tracking, mistakes can occur, leading to costly errors and wasted resources.

Consider the impact of minor inaccuracies. A few degrees off can result in misaligned components. This misalignment may seem small, but it can snowball into significant issues during production. Robots equipped with advanced seam tracking capabilities can adapt to these challenges, adjusting their paths in real time.

As technology advances, the importance of mastering seam tracking grows. It requires attention to detail and understanding the nuances of different materials and environments. Practitioners must reflect on their practices, always seeking improvement. Each project offers a chance to learn. Embracing these lessons leads to more effective seam tracking and superior outcomes in robotic applications.

Understanding Seam Tracking: Fundamentals and Importance in Robotics

Seam tracking is fundamental in robotics. It allows robots to follow a line or edge during tasks like welding or painting. Understanding the fundamentals is crucial for effectiveness. Robots need to recognize and adapt to changing environments. This adaptability enhances precision and efficiency, enabling them to work in diverse conditions.

The importance of seam tracking cannot be overstated. It impacts the quality of completed tasks directly. For instance, an incorrect seam can lead to structural failures in products. Furthermore, variations in material can affect tracking performance. Robots may struggle with inconsistencies, leading to errors. Operators must continually evaluate and improve algorithms. This reflection is necessary to ensure that the system performs well under various circumstances. Seam tracking is not just a technical process; it involves thoughtful consideration and ongoing adjustments.

10 Essential Tips for Effective Seam Tracking in Robotics

| Tip Number | Tip Description | Importance | Application Area |

|---|---|---|---|

| 1 | Understand the Basic Principles of Seam Tracking | Foundation for further learning | Welding |

| 2 | Select Appropriate Sensors for Seam Detection | Enhances accuracy | Manufacturing |

| 3 | Implement Real-Time Data Processing | Improves response time | Automated assembly |

| 4 | Use Adaptive Algorithms | Enhances performance in dynamic environments | Robotic arms |

| 5 | Regularly Calibrate the Tracking System | Maintains accuracy over time | Precision manufacturing |

| 6 | Analyze Previous Tracking Errors | Helps in refining algorithms | Quality control |

| 7 | Train Operators on Seam Tracking Techniques | Reduces human error | Workforce training |

| 8 | Invest in Quality Hardware | Essential for reliability | Robotic setups |

| 9 | Utilize Simulation Software for Testing | Identifies issues before real-world application | Development phase |

| 10 | Stay Updated with Industry Trends | Ensures competitive edge | Research and development |

Key Technologies Utilized in Seam Tracking Processes

Seam tracking is crucial in robotic applications, especially in welding and assembly. Key technologies play a significant role in optimizing this process.

Vision systems, for instance, are widely used. They provide real-time feedback, allowing robots to detect seams accurately. According to a recent industry report, over 70% of automated welding systems now incorporate advanced vision algorithms. These systems help to minimize errors and improve product quality.

Laser triangulation sensors are another essential technology. These sensors measure the distance to the seam, ensuring precise positioning. A study revealed that employing laser sensors can enhance seam tracking accuracy by up to 30%. However, integrating these sensors often presents challenges. Calibration can be time-consuming and requires expertise.

Machine learning algorithms are emerging as game-changers in seam tracking. They enable robots to learn from previous tasks, leading to better accuracy over time. Yet, machine learning requires vast amounts of data. This need can complicate implementation, especially in smaller operations. Ensuring data quality remains a critical concern for many manufacturers. Moreover, adjustments in the learning phase may slow down the overall production rate. Balancing these factors is essential for optimizing seam tracking efficiency.

Essential Sensor Types for Accurate Seam Tracking Implementation

In modern robotics, sensor technology is crucial for effective seam tracking. Accurate seam tracking enhances productivity and reduces waste. According to a recent industry report, over 40% of defects in manufacturing stem from poor seam detection. Thus, selecting the right sensors can significantly enhance accuracy.

There are several essential sensor types for seam tracking. Vision sensors are prominent; they capture high-resolution images of the workpiece. They can identify seams through advanced image processing techniques, cutting error rates by nearly 25%. Laser sensors also play a vital role. They measure distance precisely and ensure consistent seam alignment. However, they can struggle in reflective environments, causing inaccurate readings at times.

Ultrasonic sensors are another alternative. They work by emitting sound waves to detect seams, even in challenging scenarios. Still, their effectiveness can diminish in noisy environments. Each sensor type has its strengths and weaknesses. Adopting a mix of sensors can often yield satisfactory results. Striking the right balance is key for achieving high-quality seam tracking outcomes.

Challenges in Seam Tracking and Strategies for Overcoming Them

Seam tracking in robotics presents unique challenges. One major issue is the variability of seam geometry. According to industry reports, around 30% of seam tracking failures are due to inconsistent seam profiles. This inconsistency can lead to inefficient operation, affecting overall productivity. The ability of robots to adapt to changing seam contours is crucial but often underestimated.

Another challenge is environmental factors. Light reflections and surface textures can influence tracking effectiveness. Studies show that approximately 25% of errors in seam tracking occur because of these variables. To counteract this, integrating advanced sensors and machine learning algorithms is essential. These technologies can help robots recognize patterns and adapt in real-time.

Despite advances, many seam tracking methods still struggle with robustness. Inconsistent feature detection leads to misalignment issues. Reports indicate up to 20% of robotic welding processes suffer from poor tracking accuracy. This can result in defects and increased operational costs. Continuous improvement and iterative testing are vital to overcoming these limitations. Without reflection on these aspects, the development of more reliable seam tracking solutions could stall.

Best Practices for Optimizing Seam Tracking Performance in Robotics

Seam tracking in robotics is crucial for precision in tasks like welding and cutting. To optimize performance, consider the following best practices. First, ensure your sensor placement is strategic. This affects how well the system perceives the seam. Place the sensors at different angles to enhance visibility. This often requires trial and error.

Next, maintain your sensors. Regular calibration can prevent drift in measurements. Dirty sensors can lead to misinterpretation of the seam. A simple cleaning routine can make a significant difference. Also, remember that lighting conditions impact sensor effectiveness. Adjust lighting to suit the environment. It might not always be perfect, but consistent adjustments can improve results.

Finally, software algorithms play a major role. Using adaptive algorithms can help in adjusting to variations in seam positions. However, perfection isn't guaranteed. Sometimes, the algorithms fail to adapt quickly under sudden changes. It's essential to analyze these failures. Reflecting on what went wrong can lead to better strategies in the future. Balancing all these elements is key to improving seam tracking efficiency in robotics.

Related Posts

-

Why Is Seam Tracking Welding Essential for Precision in Modern Manufacturing?

-

2025 How to Enhance Robotic Performance with 3D Vision Systems in Automation

-

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

Revolutionizing Metal Fabrication with Seam Tracking Welding Technology for Precision Parts Production

-

How to Choose the Best Robot Vision System for Your Business Needs