10 Essential Tips for Servo Robot Seam Tracking Success

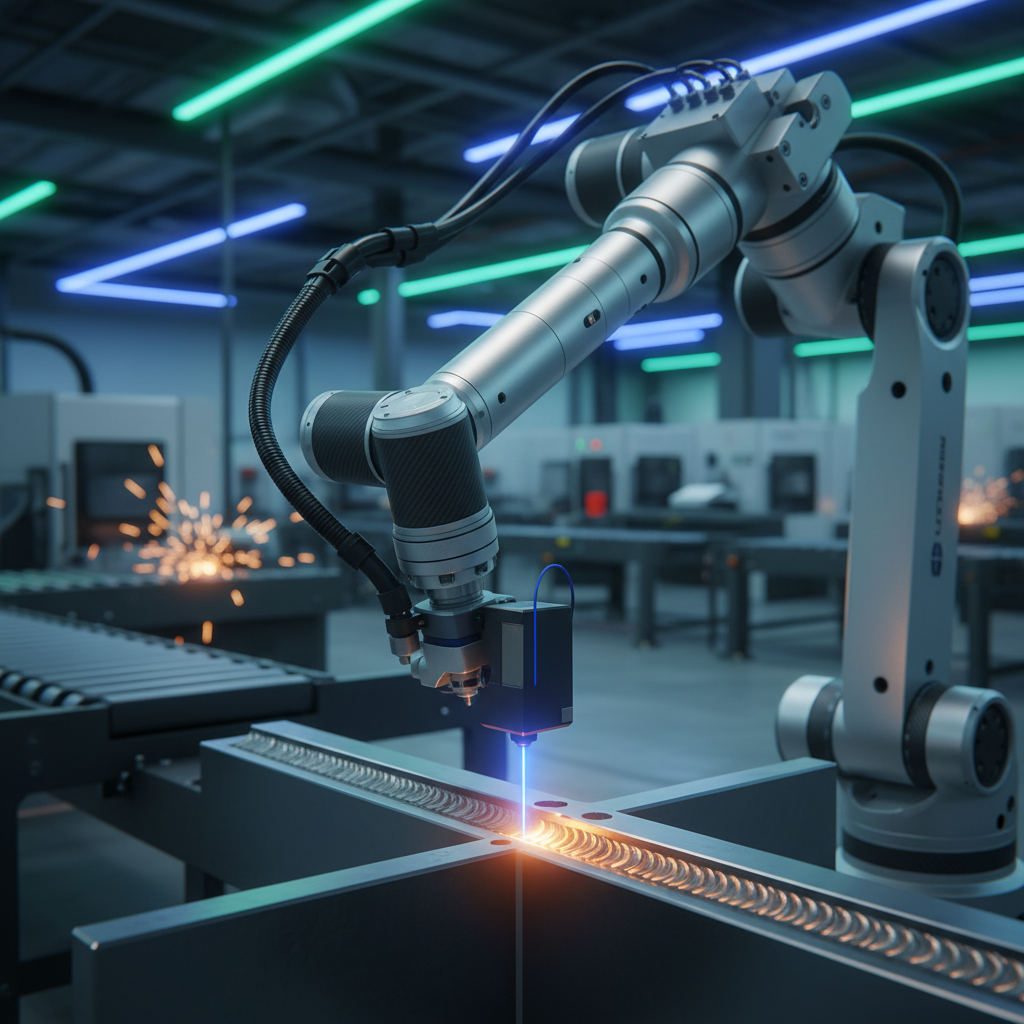

In the ever-evolving landscape of industrial automation, the integration of servo robot seam tracking technology has emerged as a pivotal component for enhancing manufacturing efficiency. Seam tracking is crucial for various applications, particularly in welding, where precision and consistency directly correlate with the quality of the final product. Achieving successful servo robot seam tracking requires not only advanced hardware but also a keen understanding of the various factors that influence performance.

This article presents "10 Essential Tips for Servo Robot Seam Tracking Success," designed to equip engineers and technicians with the knowledge they need to maximize the effectiveness of their seam tracking systems. From calibration techniques to software considerations, each tip aims to address common challenges and optimize workflow, ensuring that servo robots can navigate complex seams with ease. By implementing these strategies, manufacturers can significantly reduce errors, enhance production rates, and ultimately drive down operational costs, reaffirming the importance of servo robot seam tracking in modern manufacturing processes.

10 Advantages of Using Servo Robots for Precision Seam Tracking in Manufacturing

Servo robots have become a cornerstone in precision seam tracking for manufacturing, particularly due to their ability to enhance efficiency and accuracy. The incorporation of vision-based automatic welding guidance technology has substantially increased productivity in robotic welding applications. By leveraging an improved guidance system like the YOLOv5 algorithm paired with advanced depth cameras, manufacturers can achieve remarkable precision in seam tracking. This shift not only improves weld quality but also reduces the instances of rework, thereby minimizing production costs.

Adopting servo robots in the manufacturing process offers several advantages, including increased flexibility and adaptability. The ability to adjust quickly to different welding tasks and conditions makes servo robots a valuable asset in industries such as aerospace, where precision is critical. According to recent industry reports, implementing automated welding solutions can improve production rates by up to 30%. Additionally, servo robots are designed for enhanced repeatability, ensuring consistent outputs that meet stringent quality standards.

For success in integrating servo robots into seam tracking applications, it is essential to focus on the right strategies. One tip is to conduct thorough audits of existing processes to identify areas where automation can be most beneficial. Another key factor is investing in continuous training for operators to familiarize them with the latest technologies and techniques, thereby maximizing the potential of servo robotics in manufacturing.

Key Industry Statistics on Time Savings and Increased Productivity with Servo Robots

In recent years, servo robots have revolutionized various industries with their enhanced capabilities in seam tracking. According to a report from the International Federation of Robotics, companies that implement servo robots can see productivity increases of up to 30% and time savings of nearly 20% on repetitive tasks. This data highlights the significant advantages of integrating advanced robotics into manufacturing processes.

When it comes to successful seam tracking with servo robots, there are essential tips to consider. First, maintaining proper calibration and alignment of sensors is crucial. A well-calibrated system can reduce error rates by 15%, ensuring precise tracking along seams. Additionally, investing in quality training for operators can enhance the overall effectiveness of the robotic systems. Research from the Robotics Industries Association indicates that organizations focusing on workforce training experience a 25% improvement in operational efficiency.

Lastly, continuous monitoring and data analysis are vital for ongoing success. By analyzing performance metrics, businesses can identify areas for improvement and prevent potential downtime. Leveraging data analytics can lead to further time savings, contributing to a 40% increase in throughput, as outlined in a recent study by McKinsey. Implementing these tips will not only ensure operational efficacy but will also harness the full potential of servo robots in seam tracking applications.

Impact of Servo Robots on Time Savings and Productivity

This chart illustrates the time savings and productivity increase achieved through the use of servo robots in various industries. The data reflects how servo robots have transformed operational efficiency over the years.

Best Practices for Sensor Integration in Servo Robot Seam Tracking Applications

In servo robot seam tracking applications, effective sensor integration is crucial for achieving precise and reliable performance. The first step in this process is selecting the appropriate sensors that align with the specific requirements of the task.

High-resolution cameras and laser sensors are popular choices, as they can detect even the slightest deviations in seam alignment. It’s essential to consider factors such as environmental conditions and the type of materials being processed, as these can significantly impact sensor effectiveness.

Once the sensors are selected, proper calibration is key to optimizing their performance. Regular calibration ensures that the sensors maintain accuracy over time and adapt to any changes in the operational environment. Implementing advanced algorithms for data fusion can enhance the sensor's ability to interpret the seam's position by combining inputs from multiple sensor types. Additionally, maintaining a robust communication link between the sensors and the servo controller is vital to achieve real-time feedback, allowing for immediate adjustments during the tracking process. By prioritizing these best practices, manufacturers can maximize the efficiency and accuracy of their servo robot seam tracking systems.

Understanding the Impact of Machine Learning on Servo Robot Seam Tracking Efficiency

Machine learning is revolutionizing the efficiency of servo robot seam tracking, significantly enhancing the manufacturing capabilities across various industries. A recent report from MarketsandMarkets estimates that the global machine learning market in the manufacturing sector will reach $22.3 billion by 2024, reflecting an annual growth rate of 41.3% from 2019. This growth underscores the pivotal role of machine learning in optimizing processes, particularly in applications like seam tracking, where precision and adaptability are crucial.

Servo robots equipped with advanced machine learning algorithms can analyze real-time data from sensors to adjust their operations on-the-fly, improving accuracy in seam tracking. According to research by Gartner, organizations that implement machine learning algorithms can achieve up to a 30% reduction in defects and an increase in throughput by 20%, leading to significant cost savings. These capabilities enable manufacturers to effectively manage variations in material and environment, ensuring that the seams are consistent and up to specification, which is vital for product quality in sectors such as automotive and aerospace manufacturing.

Future Trends in Servo Robot Technology and Their Implications for Seam Tracking Success

The future of servo robot technology is poised for remarkable advancements that will significantly impact seam tracking success. With the integration of artificial intelligence and machine learning, servo robots are becoming increasingly capable of self-learning and adaptation. These innovations will enable them to recognize complex seam patterns and adjust their tracking algorithms in real-time, thus improving precision and reducing error rates in various applications, from automotive manufacturing to electronics assembly.

Moreover, the rise of advanced sensors and imaging technologies is set to revolutionize seam tracking capabilities. Enhanced visual recognition systems will allow robots to better perceive their environment, aligning their movements with greater accuracy. These trends indicate a shift toward more autonomous and intelligent servo robots that not only perform tasks but also intelligently respond to dynamic operational conditions. As these technologies evolve, their implications for productivity and quality assurance in manufacturing processes will be profound, making seam tracking not only more efficient but also more reliable than ever before.

Related Posts

-

Unlocking the Future of Automation with Advanced Robot Vision Systems

-

Top 5 Benefits of Robotic Process Automation for Modern Businesses

-

Exploring the Future of Manufacturing: How Servo Robot Seam Tracking Revolutionizes Precision Welding

-

How to Enhance Your Photography Skills with Innovative Camera Robots

-

Exploring the Future of Robotic Vision: Innovations That Transform Industries

-

Exploring the Future of Manufacturing: How Welding Robots Revolutionize the Industry