How to Leverage Robotic Vision for Enhanced Automation in 2025

As we approach 2025, the integration of robotic vision into automation processes is poised to revolutionize industries across the globe. Dr. Alice Thompson, a leading expert in the field of robotic vision, emphasizes the transformative potential of this technology, stating, "Robotic vision doesn't just enhance automation; it redefines how machines perceive and interact with the world." This paradigm shift allows not only for greater precision and efficiency but also for more adaptive and intelligent systems that can respond to dynamic environments.

The growing capabilities of robotic vision systems enable machines to interpret complex visual data and make informed decisions, thereby streamlining workflows and reducing the need for human intervention. In industries from manufacturing to logistics, the benefits are evident—from improved quality control to faster processing times. As organizations look to leverage this cutting-edge technology, understanding the nuances of implementing robotic vision will be crucial for maintaining competitive advantage.

In this context, exploring the strategies for effectively harnessing robotic vision will be essential for businesses aiming to enhance their automation capabilities. As we delve into the various facets of this topic, it becomes clear that the future of automation is not just mechanical but also visually intelligent.

The Evolution of Robotic Vision Technologies by 2025

The evolution of robotic vision technologies by 2025 is set to significantly transform the landscape of industrial automation. Advanced sensors, artificial intelligence, and machine learning algorithms will enable robots to perceive and interpret their surroundings with greater accuracy and efficiency. Enhanced image processing capabilities will allow these systems to recognize patterns, objects, and even differentiate between various materials, which will be crucial in tasks ranging from quality control to inventory management. As these technologies evolve, robots will become increasingly autonomous, allowing for seamless integration into existing workflows.

Tips for businesses looking to adopt robotic vision technologies include investing in training and support for staff to ensure they can effectively operate and troubleshoot new systems. Additionally, companies should consider starting with pilot projects to test the capabilities of robotic vision in specific applications before fully integrating them into their production lines. This approach will not only reduce risks but also provide valuable insights into how these technologies can best be utilized to enhance efficiency and productivity.

Moreover, partnerships with technology providers can facilitate access to the latest advancements in robotic vision, ensuring that businesses stay ahead of the curve. Regularly updating software and hardware will further improve the robots' performance and adaptability, making it easier for organizations to capitalize on emerging opportunities in automation by 2025.

Key Applications of Robotic Vision in Various Industries

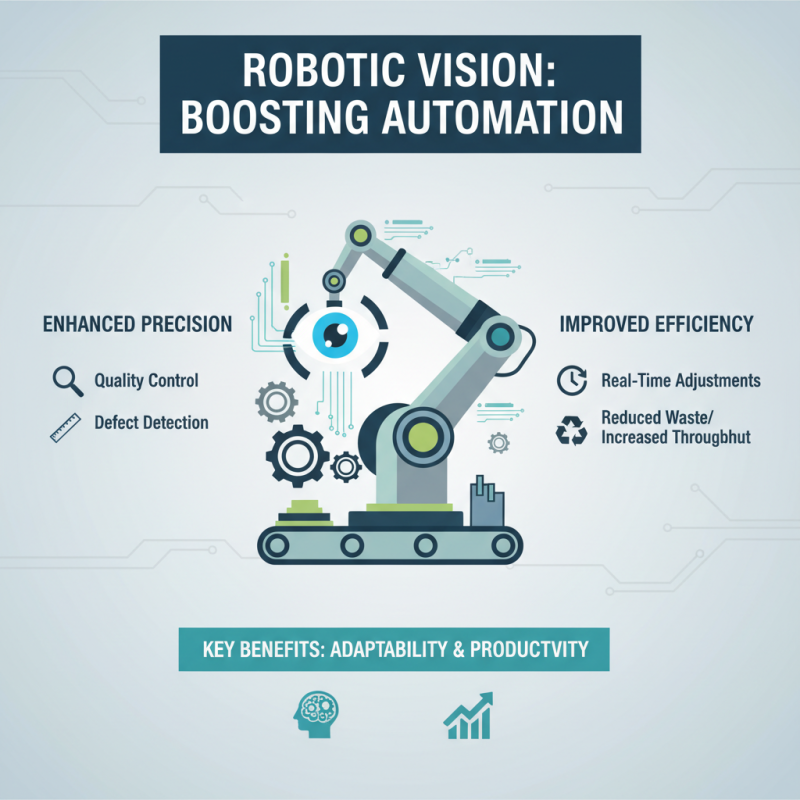

Robotic vision technology has rapidly gained traction across various industries, revolutionizing processes and enhancing automation. In manufacturing, robotic vision systems can identify, inspect, and sort products on assembly lines at unprecedented speeds and accuracy. This capability not only reduces human error but also optimizes quality control by ensuring that only products meeting specified criteria are forwarded in the supply chain. Moreover, the integration of advanced image processing algorithms allows for real-time adjustments, making manufacturing operations more adaptive and efficient.

In the healthcare sector, robotic vision plays a critical role in surgical procedures and patient monitoring. Advanced imaging technologies enable surgical robots to provide high-precision assistance during complex operations, while machine learning models analyze visual data to aid in diagnostics and treatment planning. Additionally, robotic vision systems can enhance patient monitoring by providing real-time analysis of vital signs and behaviors, allowing healthcare professionals to respond promptly to any medical emergencies. As robotic vision continues to evolve, its applications are expected to grow, further improving efficiency and outcomes in the healthcare industry.

Integrating Robotic Vision into Existing Automation Systems

Integrating robotic vision into existing automation systems holds the key to improving operational efficiency and adaptability in various industries. By enhancing traditional automation with advanced vision technologies, businesses can achieve higher levels of precision and flexibility. Robotic vision systems enable machines to perceive and interpret their environment, allowing for real-time adjustments based on varying conditions. This integration facilitates better quality control, enabling robots to identify defects or inconsistencies during production, leading to reduced waste and increased throughput.

To effectively incorporate robotic vision into current automation frameworks, organizations should focus on seamless compatibility and scalability. This involves selecting vision systems that are easily integrated with existing hardware and software platforms, ensuring minimal disruption to ongoing operations. Additionally, training personnel to understand and leverage these technologies is crucial. By fostering a culture of innovation and technical know-how, companies can maximize the benefits of robotic vision, making their automation systems not only smarter but also more responsive to changing market demands. As technologies evolve, the potential for enhanced productivity and operational excellence will become even more significant, making robotic vision an essential component of future automation strategies.

Challenges and Solutions in Implementing Robotic Vision

As industries move towards greater automation, the implementation of robotic vision systems presents both significant opportunities and formidable challenges. One of the primary challenges is the integration of advanced imaging technologies with existing automation frameworks. Many facilities utilize outdated systems that may not be compatible with modern robotics, necessitating costly upgrades or complete overhauls. Furthermore, workforce training is crucial, as operators must understand how to interact with and maintain these sophisticated vision systems. A lack of skilled personnel can hinder effective integration, leading to potential downtime and reduced operational efficiency.

Another challenge lies in the robustness and adaptability of robotic vision for diverse applications. Environments may vary dramatically, from fluctuating lighting conditions to complex and dynamic object movements. Developing algorithms that can accurately interpret visual data in real-time poses a technical hurdle for many engineers. To overcome this, investment in machine learning and artificial intelligence is essential, enabling systems to learn from their environments and improve over time. Collaborative efforts within the industry to share knowledge and advancements in computer vision can also play a pivotal role in addressing these challenges, ensuring that businesses can fully capitalize on the benefits of robotic vision by 2025.

Robotic Vision Technology Implementation Challenges and Solutions (2025)

Future Trends in Robotic Vision and Automation Technologies

In 2025, the integration of robotic vision into automation technologies is expected to revolutionize various industries by enhancing operational efficiency and precision. According to a report by MarketsandMarkets, the global robotic vision market is projected to reach $3.8 billion by 2025, growing at a compound annual growth rate (CAGR) of about 13%. This growth is largely driven by advancements in artificial intelligence and machine learning algorithms that allow robots to accurately interpret visual data, enabling them to perform complex tasks such as sorting, quality inspection, and remote monitoring with unprecedented reliability.

Emerging trends in robotic vision technology highlight the increasing capabilities of machine vision systems, particularly in industrial applications. For instance, the development of 3D vision systems is gaining momentum, allowing robots to understand their environment in a more sophisticated manner. A study by Statista indicates that 35% of manufacturers are expected to adopt advanced vision systems by 2025, significantly increasing productivity and reducing error rates. Additionally, the enhancement of collaborative robots (cobots) equipped with vision technology will facilitate more intuitive human-robot interactions, streamlining workflows across sectors such as manufacturing, logistics, and healthcare. These trends underscore the transformative impact of robotic vision on automation, paving the way for smarter, more efficient operations in the years to come.

Related Posts

-

Unlocking the Future of Automation with Digital Robotic Process Techniques

-

Top 2025 Welding Robots: Innovations Transforming the Industry

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

How to Choose the Best Robot Vision System for Your Business Needs

-

Robotic Process Innovations at the 138th Canton Fair 2025 Transforming Industry Standards in China

-

How to Choose the Right Inspection Robot for Your Industry Needs