Why Robot Vision Systems Are Transforming Industries and Shaping the Future

The rapid advancement of technology has led to the emergence of sophisticated robot vision systems that are revolutionizing various industries. These systems, which enable robots to perceive and interpret their environment through the use of cameras and sensors, are playing a critical role in enhancing automation and efficiency in operations. From manufacturing and logistics to healthcare and agriculture, the integration of robot vision systems is transforming how tasks are performed, often leading to increased productivity and reduced operational costs.

In manufacturing, for instance, robot vision systems enable machines to carry out complex inspection processes with remarkable precision, thereby minimizing errors and ensuring high quality in production lines. Similarly, in logistics, these systems facilitate autonomous navigation and real-time monitoring of inventory, optimizing supply chain management. Moreover, the adoption of robot vision systems in healthcare is ushering in new possibilities for diagnostics and surgeries, enhancing patient outcomes through advanced imaging and analysis techniques.

As we move forward, the significance of robot vision systems will only continue to grow, shaping the future landscape of various sectors. The potential benefits they offer—ranging from improved efficiency and safety to innovative solutions for existing challenges—underscore their pivotal role in the ongoing transformation of industries worldwide.

Overview of Robot Vision Systems and Their Importance

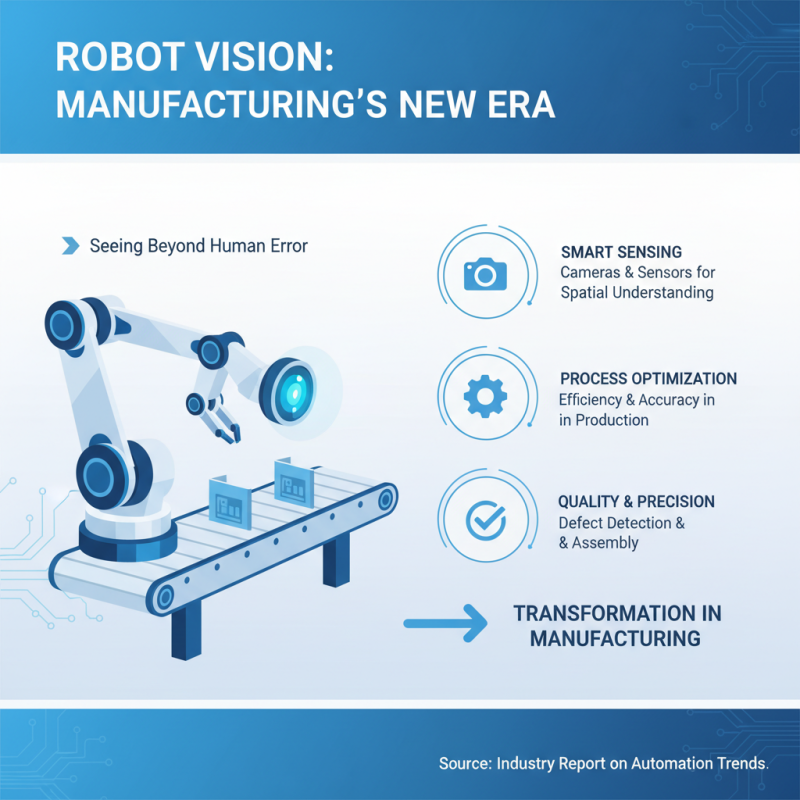

Robot vision systems have become a crucial component in various industries, significantly enhancing efficiency, accuracy, and safety. By mimicking human eyesight, these systems enable machines to perceive and interpret their surroundings, facilitating automated tasks in complex environments. The ability to identify patterns, recognize objects, and analyze visual data in real-time allows robot vision systems to optimize manufacturing processes, improve quality control, and reduce human error.

Tips: When considering the implementation of robot vision systems, ensure to assess the specific needs of your industry. This includes evaluating the types of tasks that can benefit from automation and determining the required level of precision for those tasks. Collaborating with experts in robotics and machine learning can also streamline the integration process, making it more effective and tailored to your operational requirements.

Moreover, the importance of robot vision extends beyond just operational efficiency; it also enhances workplace safety. By utilizing advanced visual capabilities, these systems can monitor hazardous conditions and prevent accidents. This shift not only helps protect workers but also promotes a culture of safety within industrial environments. Embracing this technology is crucial for companies that aim to stay competitive and innovative in the rapidly evolving landscape of automation.

Key Technologies Driving Robot Vision Innovations

Robot vision systems are poised to revolutionize a wide array of industries by integrating advanced technologies that enhance automation and operational efficiency. Key among these technologies are artificial intelligence algorithms, which enable robots to interpret visual data and make real-time decisions. According to a report by MarketsandMarkets, the global market for AI in the visual inspection segment is expected to grow from $2.5 billion in 2021 to $5.0 billion by 2026, reflecting a compound annual growth rate (CAGR) of 15.1%. This growth is indicative of the increasing reliance on AI-driven visual systems to ensure quality control and streamline production processes.

Another crucial technology driving innovations in robot vision is machine learning, which allows systems to improve their accuracy over time through experience. A significant finding from a study by Grand View Research revealed that the machine vision market is projected to reach $12.96 billion by 2028, expanding at a CAGR of 7.5%. This surge is largely due to advancements in deep learning techniques that enable robots to recognize patterns and anomalies in complex environments, making them invaluable across sectors such as manufacturing, logistics, and healthcare. As industries continue to adopt these transformative technologies, the implications for efficiency, safety, and productivity are profound, paving the way for smarter robotics in the future.

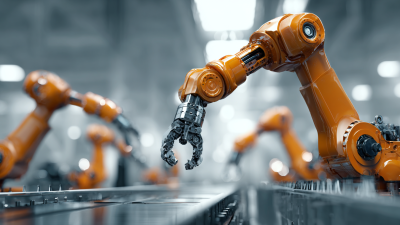

Applications of Robot Vision in Manufacturing Industries

The manufacturing industry is experiencing a significant transformation thanks to advancements in robot vision systems. These systems use cameras and sensors to enable robots to understand and interpret their surroundings, leading to greater efficiency and accuracy in production processes. From quality control to assembly line operations, robot vision is playing a critical role in ensuring that products meet high standards while reducing human error.

For instance, in quality inspection, robot vision systems can swiftly identify defects in products by analyzing visual data far more quickly than a human inspector. This not only enhances the consistency of product quality but also speeds up the inspection process, allowing for increased throughput. Moreover, robot vision aids in the automation of assembly tasks by ensuring parts are correctly aligned before they are joined together, reducing the risk of costly mistakes.

Tips: When implementing robot vision systems in your manufacturing processes, consider starting with a pilot project. This allows you to assess the benefits and challenges in a controlled environment before a full-scale rollout. Additionally, ensure your team is well-trained in interpreting the data provided by these systems, as understanding the insights generated is key to optimizing operations.

Impact of Robot Vision on Efficiency and Productivity

Robot vision systems are revolutionizing industries by significantly enhancing efficiency and productivity across various sectors. These advanced systems employ sophisticated algorithms and sensors to interpret visual data, enabling robots to identify objects, assess their conditions, and make decisions in real-time. By automating these processes, businesses can streamline their operations, reduce human error, and optimize resource allocation. The consistency and precision provided by robot vision allow for faster production cycles and better quality control, leading to an increase in overall output.

Moreover, the integration of robot vision technology into supply chain management and logistics has been a game changer. Automated systems equipped with vision capabilities can rapidly sort and categorize products, track inventory levels, and even conduct inspections, all while minimizing downtime. As a result, companies benefit from enhanced operational agility and can respond more effectively to fluctuating market demands. The ability to gather and analyze visual data in real-time also enables businesses to make informed decisions swiftly, ultimately driving innovation and sustaining competitive advantage in an ever-evolving marketplace.

Why Robot Vision Systems Are Transforming Industries and Shaping the Future

| Industry | Impact on Efficiency (%) | Impact on Productivity (%) | Cost Reduction (%) |

|---|---|---|---|

| Manufacturing | 25% | 30% | 20% |

| Logistics | 20% | 25% | 15% |

| Healthcare | 30% | 35% | 10% |

| Agriculture | 15% | 20% | 18% |

| Retail | 18% | 22% | 12% |

Future Trends and Challenges in Robot Vision Development

The development of robot vision systems is rapidly advancing, driven by the need for increased efficiency and precision in various industries. According to a market research report from Fortune Business Insights, the global robot vision market is expected to reach $4.2 billion by 2027, expanding at a compound annual growth rate (CAGR) of 12.6% from 2020. This growth can be attributed to the rising adoption of automation solutions and the integration of artificial intelligence in robot vision technology. As industries increasingly move toward automation, the demand for sophisticated vision systems capable of executing complex perception tasks will continue to rise.

However, the evolution of robot vision systems is not without its challenges. One significant hurdle lies in the development of algorithms that can accurately interpret visual data in real-time. A study from the International Journal of Robotics Research highlights that achieving reliable computer vision still requires overcoming issues related to varying lighting conditions and object recognition in dynamic environments. Additionally, the integration of machine learning techniques poses questions about data privacy and the ethical use of visual data. With these challenges, robust frameworks must be established to ensure that robot vision systems not only enhance productivity but also adhere to safety and ethical standards within their operational contexts. As industries embrace these technologies, navigating these trends and challenges will be crucial for successful implementation.

Impact of Robot Vision Systems Across Different Industries

This chart illustrates the adoption rates of robot vision systems across various industries, highlighting the transforming impact these technologies have. Manufacturing leads with an 85% adoption rate, followed by healthcare and agriculture, showcasing the diverse applications of robot vision in enhancing operational efficiency and innovation.

Related Posts

-

Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

-

Top 10 Amazing Innovations in Robot Vision Technology You Need to Know

-

How to Choose the Best Robot Vision System for Your Business Needs

-

Unlocking the Future of Automation with Advanced Robot Vision Systems

-

Top 10 Tips for Choosing the Right Inspection Robot for Your Industry

-

How to Master Robotic Arc Welding: Tips, Techniques, and Best Practices