How to Use Robotic Vision for Enhanced Automation and Efficiency

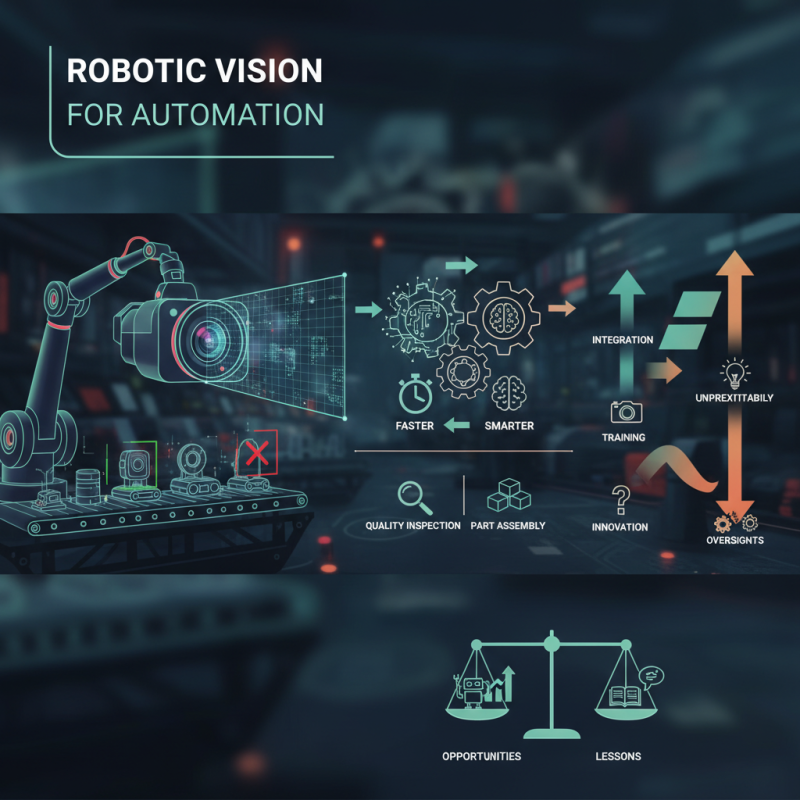

In today's fast-paced industrial landscape, robotic vision is transforming automation practices. Experts like Dr. Emily Torres say, "Robotic vision is the key to unlocking greater efficiency." This technology enables machines to see and interpret their surroundings. As a result, operations become not just faster but smarter.

Robotic vision allows for intricate tasks like quality inspection and part assembly. Machines equipped with advanced cameras can identify defects that human eyes might miss. However, reliance on this technology can lead to oversights. Issues may arise if systems fail to adapt to complex environments.

As industries embrace robotic vision, challenges persist. The integration of vision systems requires careful planning. Training is essential, as machines must learn from real-world scenarios. Businesses often find themselves balancing innovation with the unpredictability of these systems. In the end, the journey towards full automation with robotic vision offers both opportunities and lessons to learn.

Understanding Robotic Vision and Its Importance in Automation

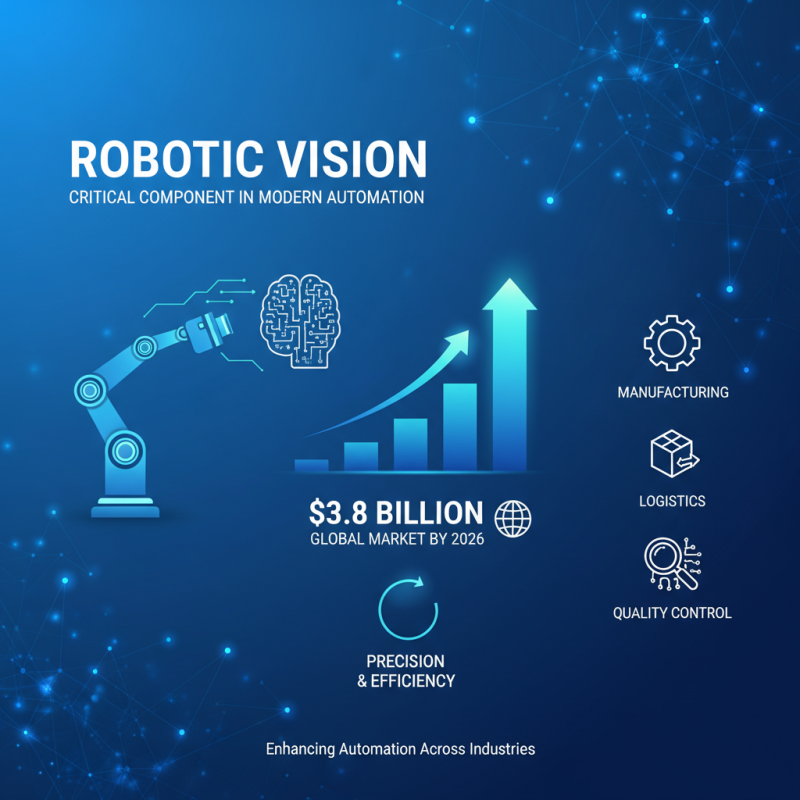

Robotic vision is a critical component in modern automation. It allows machines to interpret and analyze visual data, enhancing precision. According to a report by MarketsandMarkets, the global robotic vision market is projected to reach $3.8 billion by 2026. This growth reflects the increasing reliance on automation in various industries, from manufacturing to logistics.

As businesses integrate robotic vision systems, they gain the ability to perform complex tasks. For example, robots can identify defects in products or locate items in a warehouse. This capability reduces human error and increases productivity. However, implementing robotic vision is not without challenges. Companies must ensure proper calibration and maintenance to avoid inaccuracies.

Tip: Start with simple applications to test the technology. Gradual implementation allows for adjustments and fine-tuning.

Another area to reflect on is system compatibility. Integrating new vision systems with existing automation processes might present obstacles. Ensuring a seamless connection between robotic vision and existing equipment is essential for overall effectiveness.

Tip: Conduct thorough compatibility assessments before full-scale deployment. This can help identify potential issues early on.

Key Components of Robotic Vision Systems for Efficiency

Robotic vision systems are transforming automation. These systems enable machines to perceive their surroundings with precision. Cameras and sensors gather visual data, which the software then interprets. This enhances operational efficiency in various tasks. For instance, vision systems can identify defects in products quickly. This reduces waste and speeds up production.

Key components of robotic vision include cameras, lighting, and image processing algorithms. Cameras capture images in real time. Proper lighting is essential for clear visibility. Without it, the cameras may misinterpret objects. Image processing algorithms analyze the images, extracting crucial information. This step often requires sophisticated programming and can pose challenges.

Another component is the integration with existing systems. Seamless communication between machines is vital. However, mismatched protocols can lead to errors. In some cases, unforeseen issues arise during implementation. It’s important to adapt and refine the systems continuously. Adjustments may be necessary for optimal performance.

Robotic Vision System Efficiency Improvements

Applications of Robotic Vision in Various Industries

Robotic vision is transforming various industries. For instance, in manufacturing, it improves product quality through precise inspections. A recent report from the International Federation of Robotics states that robotic automation could yield a productivity increase of up to 30% in factories. This technology allows machines to detect defects at high speeds, reducing waste and ensuring a consistent output.

In logistics, robotic vision helps in tracking inventory and optimizing warehouse operations. Companies utilizing these systems have reported a reduction in order fulfillment time by 25%. However, integrating robotic vision systems can be challenging. Data from industry experts suggests that over 40% of organizations face obstacles in training staff to work effectively with new technologies.

Tip: Invest in employees' training programs. Understanding technology is key for smooth operations. Another suggestion is to start small. Test robotic vision in one area before implementing it across the entire operation. This approach allows for adjustments based on initial results. Monitoring performance is essential, as every system may not deliver immediate benefits. Regular reviews help in identifying areas needing improvement.

Challenges and Solutions in Implementing Robotic Vision Technology

Robotic vision technology is rapidly transforming industries. However, implementing it poses significant challenges. A recent report by the International Federation of Robotics highlighted that over 40% of companies reported difficulties in integrating vision systems with existing machinery. Lack of technical expertise is often a barrier. Many organizations struggle to find skilled workers who can manage these advanced technologies.

Data from the Business Insights Group indicates that 30% of failed robotic vision projects are due to poor system calibration. Accurate calibration is vital for optimal performance. Furthermore, many businesses underestimate the complexity of data processing. Simple mishaps in image processing can lead to costly mistakes. For example, improper image recognition can result in defective products reaching consumers.

Moreover, aligning robotic vision systems with dynamic environments presents ongoing hurdles. Many factories change layouts frequently, leading to disruptions in robotic vision effectiveness. Adapting these technologies to new situations demands continuous evaluation and improvement. As industries strive for enhanced automation, addressing these challenges is crucial for success. Efficient implementation requires careful planning and dedicated resources.

Future Trends in Robotic Vision and Its Impact on Automation

The future of robotic vision holds significant promise for automation. This technology allows machines to interpret visual data efficiently. Enhanced image processing enables robots to identify objects, navigate spaces, and perform complex tasks. New algorithms make it easier for machines to learn from their surroundings. However, challenges remain in achieving flawless recognition and adaptation.

As robotic vision evolves, it impacts various industries. Factories utilize visual systems for quality control. But not every vision system works perfectly. In some cases, misidentifications occur. These errors can lead to production delays. Engineers must refine algorithms continuously to minimize mistakes.

Looking ahead, companies must invest in research to enhance robotic vision. The integration of machine learning offers huge potential. But companies face obstacles related to cost and implementation. Balancing innovation and financial viability is crucial. Exploring the intersection of vision technology and automation will shape the workforce of the future. The potential is exciting, yet it also invites scrutiny and improvement as industries adapt.

Related Posts

-

Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

-

Top 10 Amazing Innovations in Robot Vision Technology You Need to Know

-

What is Robotic Vision? Understanding Its Importance and Applications in Automation

-

How to Leverage Robotic Vision for Enhanced Automation in 2025

-

How to Choose the Best Robot Vision System for Your Business Needs

-

Top Robotic Vision Technologies Transforming Industries Today