What is Robotic Vision? Understanding Its Importance and Applications in Automation

Robotic vision is a transformative technology that plays a pivotal role in the advancement of automation across various industries. As machines increasingly assume tasks traditionally performed by humans, the ability to "see" and interpret the environment is crucial for the effectiveness of such systems. Dr. Carla Smith, a leading expert in the field of robotic vision, emphasizes its significance by stating, "Robotic vision is not just about mimicking human sight; it’s about enhancing precision and efficiency in automation processes."

This powerful technology enables robots to identify objects, navigate spaces, and make decisions based on visual input, thus enhancing operational productivity and safety. From manufacturing lines that rely on computer vision for quality control to autonomous vehicles that use advanced sensors to navigate through complex environments, the applications of robotic vision are vast and varied. As automation continues to evolve, understanding the intricacies of robotic vision will remain essential for industries aiming to thrive in an increasingly automated world.

The Basics of Robotic Vision: Definition and Components

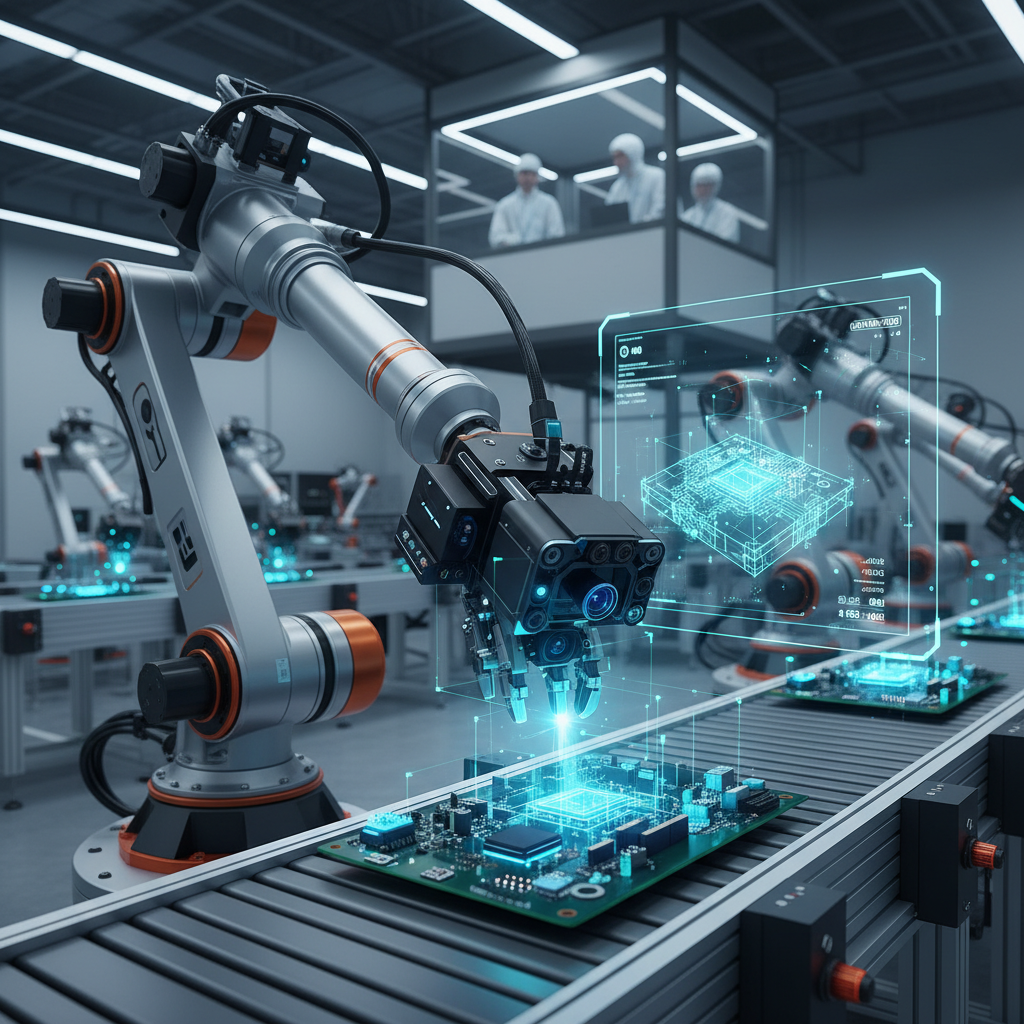

Robotic vision is a technology that enables machines to perceive and interpret their surroundings through visual data. At its core, robotic vision comprises several key components: cameras, image processing software, and algorithms. Cameras capture visual information, which is then processed by software to extract meaningful features. These algorithms enable robots to make decisions based on visual input, enhancing their ability to interact with the environment.

When designing a robotic vision system, it's crucial to select the right type of camera for your application. Tips for choosing the appropriate camera include considering the resolution needed for accuracy and the lighting conditions of the environment. Additionally, utilizing advanced image processing techniques can significantly improve the robot’s ability to distinguish between different objects.

Another essential aspect is the integration of machine learning algorithms. Tips for successful integration involve training models with diverse datasets to enhance their accuracy in recognizing and interpreting various visual cues. By implementing robust robotic vision systems, industries can significantly improve automation efficiency, reducing errors and optimizing processes.

The Significance of Robotic Vision in Automation Industries

Robotic vision is revolutionizing the automation industries by enhancing the capabilities of machines to perceive and interpret their surroundings. According to a recent report by MarketsandMarkets, the global robotic vision market is projected to reach USD 3.3 billion by 2026, growing at a CAGR of 9.5%. This technology integrates advanced imaging systems and artificial intelligence, allowing robots to execute tasks with precision and reliability that surpass human capabilities. The significance lies in its application across various sectors, including manufacturing, logistics, and healthcare, where visual data is crucial for process optimization and quality control.

In manufacturing, robotic vision systems enable automation of inspection processes, drastically improving accuracy and reducing error rates. As highlighted by a study from McKinsey, companies that implement vision-enabled robotics can achieve a productivity increase of up to 20%. This leap not only enhances operational efficiency but also allows businesses to allocate resources more effectively, reinforcing their competitive edge.

**Tips for Implementing Robotic Vision:**

1. Assess your operational needs: Identify areas where robotic vision can offer immediate benefits.

2. Invest in training: Ensure your workforce understands the integration of robotic vision into existing workflows to maximize its potential.

3. Start small: Pilot projects can help troubleshoot challenges before a full-scale implementation, ensuring a smoother transition.

Robotic Vision Importance in Automation Industries

Key Applications of Robotic Vision Across Various Sectors

Robotic vision is revolutionizing numerous sectors by enhancing automation capabilities. In manufacturing, for instance, the Global Market Insights report indicates that the robotic vision market is projected to reach $3.5 billion by 2026, driven by demand for high-quality inspection and precision in assembly lines. This technology enables machines to understand and interpret visual information, leading to improved efficiency and reduced error rates.

Industries such as automotive and electronics leverage robotic vision for intricate tasks such as sorting and quality control, ensuring consistency and reliability in production processes.

Robotic vision is revolutionizing numerous sectors by enhancing automation capabilities. In manufacturing, for instance, the Global Market Insights report indicates that the robotic vision market is projected to reach $3.5 billion by 2026, driven by demand for high-quality inspection and precision in assembly lines. This technology enables machines to understand and interpret visual information, leading to improved efficiency and reduced error rates.

Industries such as automotive and electronics leverage robotic vision for intricate tasks such as sorting and quality control, ensuring consistency and reliability in production processes.

In logistics and warehousing, robotic vision systems optimize the management of inventory and streamline operations. With the rise of e-commerce, companies now report that implementing robotic vision solutions can improve packaging and sorting speed by up to 30%. This is crucial for maintaining competitiveness in today's fast-paced market. Furthermore, in the healthcare sector, robotic vision assists in surgeries, providing surgeons with enhanced visual feedback and precision for intricate procedures.

Tips: When considering the integration of robotic vision into your business, ensure you conduct a thorough assessment of your specific needs and tools available. Look into systems that offer versatile applications across different processes for better investment value. Additionally, stay updated on technological advancements, as continuous improvements can significantly enhance operational efficiency.

Future Trends: Innovations Shaping Robotic Vision by 2025

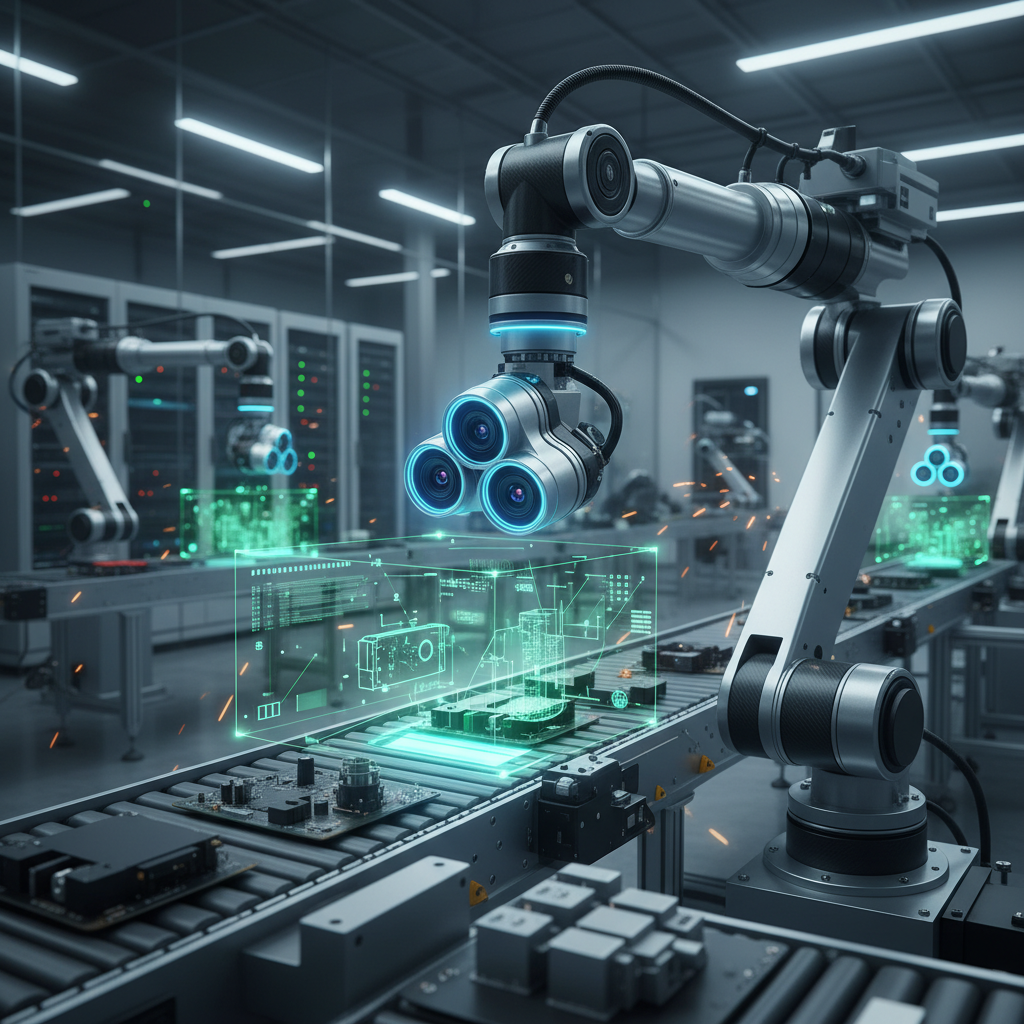

Robotic vision is rapidly evolving, marking a pivotal transformation in automation. By 2025, several innovative trends are expected to redefine this field. One major trend is the advancement in artificial intelligence algorithms, which enhance the accuracy and efficiency of robotic vision systems. These smarter algorithms enable robots to better interpret visual data, allowing them to perform complex tasks with remarkable precision.

Moreover, the integration of 3D imaging technology is set to revolutionize how robots perceive their environment. This technology allows for a more nuanced understanding of spatial relationships, which is essential in manufacturing and logistics. As robots gain the ability to perceive depth and texture, they can handle a wider variety of materials safely and effectively.

**Tips:** When considering the implementation of robotic vision in your operations, assess the specific tasks that could benefit from enhanced visual capabilities. Keep an eye on emerging technologies and invest in training for your team to adapt to these innovations smoothly. Regularly updating your systems and staying informed on industry trends will ensure that you remain competitive as robotic vision advances.

Challenges and Solutions in Implementing Robotic Vision Systems

Robotic vision plays a crucial role in automation, enabling machines to interpret and understand visual data from their environment. However, implementing robotic vision systems comes with several challenges. One of the primary issues is the variability in lighting conditions, which can significantly affect the performance of image recognition algorithms. Additionally, the complexity of the objects being observed—such as their shapes, textures, or colors—can lead to inaccuracies in image processing.

To overcome these challenges, it is essential to incorporate robust calibration techniques and adaptive algorithms that can learn and adjust to different conditions. Implementing machine learning models can also enhance the system's ability to recognize and classify objects in diverse environments.

**Tips:** When integrating robotic vision systems, prioritize high-quality cameras and sensors that can function effectively in varied lighting. Regularly update your algorithms using real-world data to improve accuracy in diverse operational conditions. Additionally, conducting thorough tests in different scenarios can help identify potential errors and refine your system before full deployment.

Related Posts

-

Revolutionizing Industries: How Robot Vision Systems Enhance Automation and Efficiency

-

Top 10 Amazing Innovations in Robot Vision Technology You Need to Know

-

Unlocking the Future of Automation with Advanced Robot Vision Systems

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

Exploring the Future of Robotic Process Automation for Business Efficiency

-

Robotic Process Innovations at the 138th Canton Fair 2025 Transforming Industry Standards in China