Top 10 Inspection Robots You Need to Know About?

In the evolving landscape of technology, inspection robots are making their mark. Renowned industry expert Dr. Emily Chen emphasizes this shift, stating, "Inspection robots are revolutionizing how we see and repair our infrastructure." These robots use advanced sensors and cameras to collect data in real time. They can access hard-to-reach places that human inspectors often struggle to navigate safely.

The growing reliance on these machines raises important questions. Are we overly dependent on technology for inspections? As businesses deploy inspection robots, we must consider their limitations. Accuracy can sometimes be compromised in challenging environments. The human touch in assessments may still be irreplaceable, especially in complex scenarios.

Furthermore, while inspection robots are efficient, their implementation requires careful thought. Maintenance and calibration issues can arise, highlighting a need for ongoing training. The future of inspection robots is bright, but it is crucial to strike a balance. Ultimately, understanding their capabilities and limitations will guide their successful integration into various industries.

Overview of Inspection Robots and Their Importance

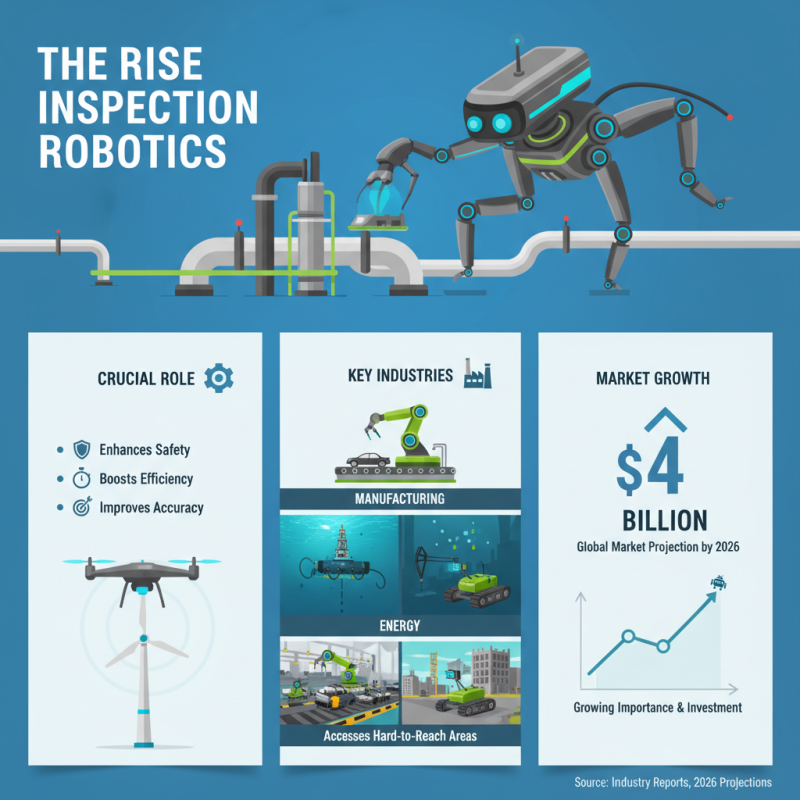

Inspection robots play a crucial role in various industries. They enhance safety, efficiency, and accuracy. In sectors such as manufacturing, energy, and construction, these robots gather data from hard-to-reach areas. Reports indicate that the global inspection robotics market is projected to reach $4 billion by 2026, highlighting their growing importance.

Using inspection robots reduces human risk. They operate in hazardous environments, such as nuclear plants or offshore oil rigs. However, some industries still rely on traditional methods. This reluctance can stem from concerns about initial costs or a lack of understanding. Companies that hesitate may miss the opportunity to improve operational safety and reduce downtime.

Tip: Always assess the specific needs of your operations before integrating robots. Understand where they can provide the most value. Data shows that early adopters have seen a 30% reduction in inspection times. Yet, it’s important to balance automation with skilled human oversight.

Inspection robots should complement human workers. They can collect data, but they need human insights for full effectiveness. As technology advances, it's vital to stay informed about these tools' capabilities and limitations. Keep exploring new options; the future of inspection is evolving.

Key Features to Consider When Choosing an Inspection Robot

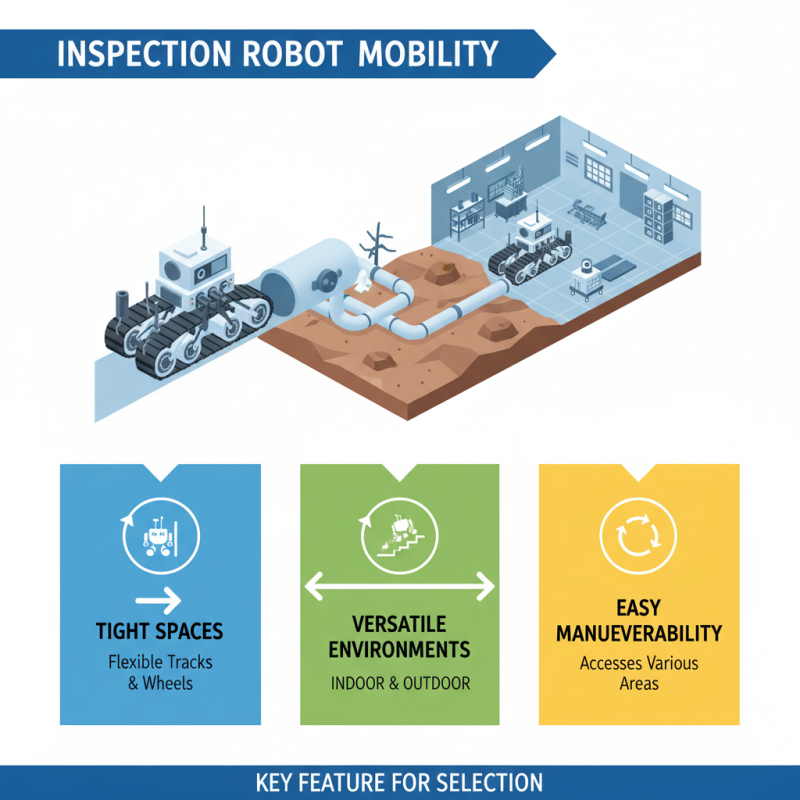

When selecting an inspection robot, consider its mobility. A good robot should navigate through tight spaces easily. Look for models with flexible tracks or wheels. This feature allows access to various environments. Your robot should be able to maneuver indoors and outdoors.

Another key feature is sensor technology. High-quality cameras and thermal sensors are essential. They provide critical data for inspections. Ensure the robot has a reliable imaging system. This capability helps in identifying potential issues early.

Tips: Test the robot's agility in different terrains. A stationary design may limit inspection capabilities. Also, check the battery life. Short runtimes can disrupt inspections. Evaluate the ease of software integration too. Complex systems can hinder efficiency. Always think about user experience when making your choice.

Top 10 Innovative Inspection Robots in Various Industries

Inspection robots are revolutionizing various industries. From manufacturing to infrastructure, these technological marvels enhance efficiency and safety. They navigate complex environments with ease. Some rely on advanced cameras to capture detailed visuals. Others use sensors to detect anomalies and potential issues.

In the construction industry, robots scout inaccessible areas. They identify faults in structures before they become serious. However, some robots still struggle in harsh weather. This limitation can hinder their effectiveness on job sites. Furthermore, many robots require significant programming to function optimally, leaving room for improvement.

The energy sector benefits greatly from inspection robots. They inspect pipelines and power grids efficiently. Remote areas no longer pose a challenge. Yet, some robots face difficulties in interpreting data accurately. This can lead to missed warnings. Addressing these obstacles will be crucial for future developments. As technology evolves, so will the capabilities of inspection robots across industries.

Top 10 Innovative Inspection Robots in Various Industries

| Robot Model | Industry | Key Features | Operating Range | Battery Life |

|---|---|---|---|---|

| InspectionBot A | Manufacturing | High-resolution cameras, AI analysis | Up to 100m | 8 hours |

| Inspecto 3000 | Oil & Gas | Thermal imaging, GPS navigation | 500m | 10 hours |

| RoboCheck | Construction | 3D mapping, real-time reporting | 200m | 6 hours |

| AquaInspect | Marine | Underwater capability, sonar | 1km | 5 hours |

| SafetyDrone | Building Inspection | High-altitude flight, HD video | Up to 300m | 25 minutes |

| PipeVision | Utilities | Inner pipe inspection, flexible design | 300m | 7 hours |

| DroneEye | Agriculture | Crop health monitoring, aerial imagery | Up to 5km | 30 minutes |

| FlexiBot | Logistics | Obstacle avoidance, path optimization | 150m | 12 hours |

| CheckMate | Pharmaceutical | Sterility checks, QA automation | 100m | 8 hours |

| UrbanScout | Urban Planning | Traffic analysis, urban data collection | 3km | 15 hours |

Comparative Analysis of Inspection Robots: Capabilities and Limitations

Inspection robots are revolutionizing industries such as manufacturing, construction, and energy. These robots come equipped with various sensors and cameras. They can navigate complex environments. However, despite their capabilities, there are limitations to consider. For example, some robots struggle with unstructured environments. They may not perform well in cluttered or dynamic areas. This can hinder their effectiveness in real-world applications.

Another aspect to analyze is the data processing capabilities of these robots. Some models provide real-time data. Others may require extensive post-processing. This can delay important decisions. Additionally, the cost of advanced inspection robots can be high. Smaller companies may find it difficult to invest. There is also the human factor—some operators may lack training. Misinterpretation of the data can occur without proper knowledge.

Moreover, the adaptability of inspection robots varies greatly. Some are designed for specific tasks only. Others have modular designs, allowing for upgrades. This flexibility can be beneficial, but also confusing when choices must be made. Balancing capabilities with limitations is crucial for organizations adopting these technologies. Understanding both sides can lead to better implementations of inspection robots in diverse settings.

Future Trends in Inspection Robotics and Emerging Technologies

Inspection robotics is evolving rapidly. The demand for these technologies is growing. A report by MarketsandMarkets predicts the inspection robotics market will reach $3.5 billion by 2026. This growth is driven by the need for efficiency and safety in various industries.

Several emerging technologies are influencing this sector. AI and machine learning enhance robotic capabilities. They allow robots to analyze data in real-time. This could lead to smarter decisions during inspections. Drones equipped with advanced sensors can perform intricate inspections in hard-to-reach areas. According to a study, 70% of companies using drones saw reduced inspection times.

Tips: Incorporating AI in inspection can cut costs. Consider training robots to handle specific tasks. This optimization may prove essential. Furthermore, using modular designs can improve maintenance and adaptability. It's a reflection of shifting industry needs. Flexibility in design is becoming critical for the future.

The industry is grappling with challenges as well. The reliability of robots in extreme conditions varies. While advancements are impressive, they aren't foolproof. Maintenance and software updates require regular attention. Many firms still hesitate to fully embrace these technologies. Balancing innovation with practicality remains a work in progress. A deeper understanding of these factors is essential for future advancements.

Related Posts

-

How to Leverage Robotic Vision for Enhanced Automation in 2025

-

How to Use Robotic Vision for Enhanced Automation and Efficiency

-

Exploring the Future of Robotic Laser Welding in Advanced Manufacturing Techniques

-

10 Essential Tips for Effective Seam Tracking in Robotics

-

Top 5 Benefits of Robotic Process Automation for Modern Businesses

-

10 Best Intelligent Robot Innovations Changing Our Lives?