Top Industrial Robot Types You Should Know About?

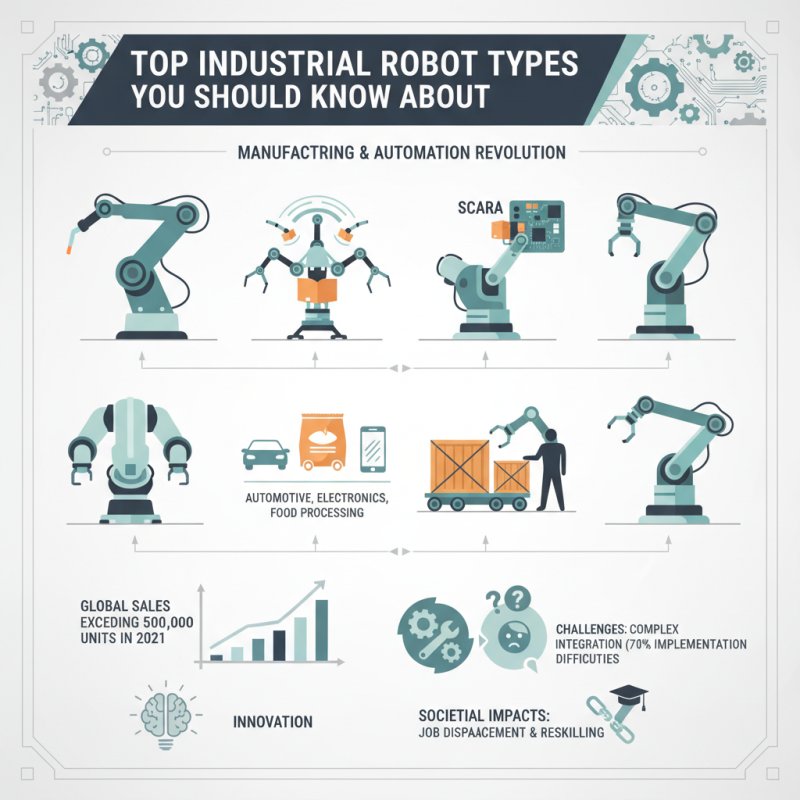

Industrial robots have revolutionized manufacturing and automation. According to a recent report by the International Federation of Robotics, global sales of industrial robots reached a record high in 2021, exceeding 500,000 units. This surge highlights the increasing reliance on these machines across various sectors, including automotive, electronics, and food processing.

The versatility of industrial robots is remarkable. They perform tasks like welding, packaging, and assembly with precision and speed. However, challenges persist. Integration can be complex, and some industries struggle to adapt. A report by McKinsey states that up to 70% of companies that invest in automation experience difficulties during implementation.

As we explore the top types of industrial robots, it’s essential to reflect on their role in reshaping production. Understanding these machines can open doors to innovation. But we must also consider the societal impacts, such as job displacement and the need for reskilling. The conversation around industrial robots is not just about technology; it’s about our future.

Types of Industrial Robots Used in Manufacturing Today

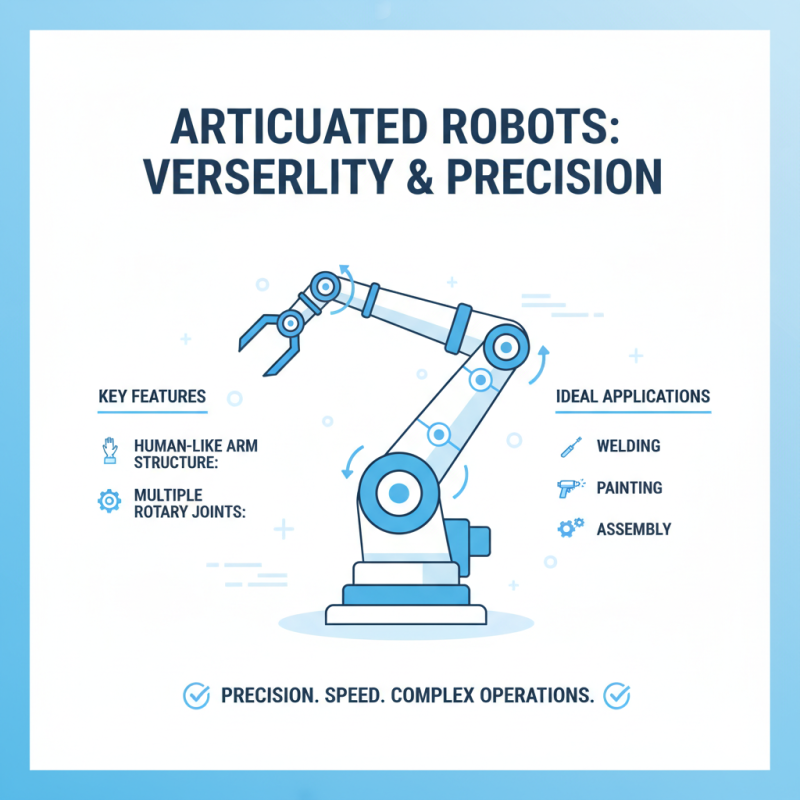

In today's manufacturing landscape, various types of industrial robots play a crucial role. Articulated robots are widely used for their flexibility. They have multiple joints, allowing them to perform complex tasks. These robots excel in assembly, welding, and painting processes. Their range of motion mimics human arms, which can enhance precision.

Another type is the SCARA robot, designed for high-speed tasks. These robots are particularly effective in assembly lines, handling repetitive tasks with ease. Their rigid structure ensures stability while moving parts quickly. However, they may lack versatility compared to articulated robots. This can limit their utility in certain manufacturing scenarios.

Parallel robots offer an interesting option as well. Known for their stability and speed, they are often used in packaging and material handling. Their design allows for quick movements and precise placements. Yet, their complexity can pose challenges in programming and maintenance. Evaluating the best type of robot for specific applications often requires careful consideration of performance and flexibility. Finding the right balance can lead to improved efficiency in production lines.

Key Features of Articulated Robots and Their Applications

Articulated robots are among the most versatile types of industrial robots. They feature a series of rotary joints that mimic a human arm. This structure allows for a wide range of movement, making them ideal for tasks like welding, painting, and assembly. The flexibility of articulated robots makes them suitable for complex operations requiring precision and speed.

These robots can handle heavy loads with ease. This quality is particularly important in manufacturing environments. Companies often employ articulated robots for tasks that demand both strength and flexibility. For instance, they are frequently used in automotive assembly lines, where they assemble various car components with meticulous accuracy. Their ability to adapt to different tasks is a notable advantage.

However, deploying articulated robots is not without challenges. Their programming can be complex, requiring skilled operators. There’s a learning curve for staff to maximize the robots' potential. Additionally, the initial investment in articulated robots may be significant, posing a barrier for small businesses. As industries adopt these robots, careful consideration of these factors is vital for successful integration into the workflow.

Understanding Cartesian Robots and Their Benefits in Industry

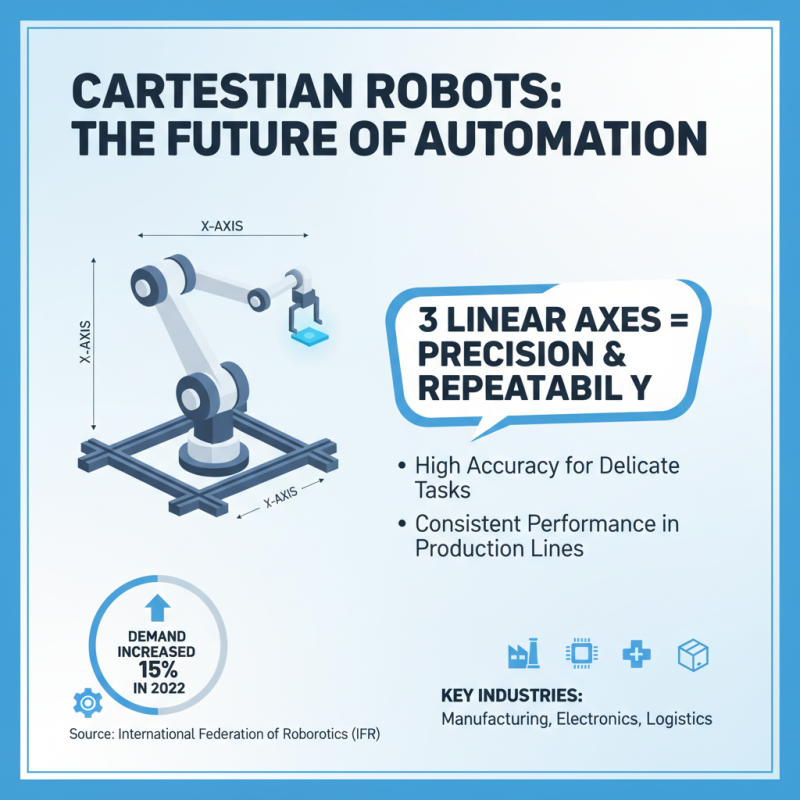

Cartesian robots are becoming increasingly important in various industries. These robots are defined by their three linear axes, resembling a Cartesian coordinate system. They excel in tasks requiring precision and repeatability. According to a report from the International Federation of Robotics, the demand for Cartesian robots grew by 15% in 2022, reflecting their rising prominence in automated settings.

One of the main benefits of Cartesian robots is their versatility. They can perform various functions, from assembly to packaging. Their simplicity allows for easier programming and integration into existing systems. Many factories have noted a 30% increase in productivity after incorporating Cartesian robots. However, their limited range of motion can sometimes hinder operations. For tasks requiring complex movements, this can be a drawback.

While Cartesian robots often enhance efficiency, challenges remain. Not all tasks are suited for their linear movements. Industries might still need to explore other robot types for those complex applications. Additionally, the initial setup can be time-consuming and may require specialized knowledge. It's essential to weigh the benefits against these challenges when considering automation solutions.

The Role of SCARA Robots in Precision Assembly Tasks

SCARA robots have become essential in precision assembly tasks. These robots are known for their unique design, featuring a two-axis parallel arm. This structure allows for efficient lateral movement. Their capability to move in a precise, controlled manner makes them ideal for intricate assembly. They can handle small parts with ease, which is crucial in industries like electronics.

However, relying on SCARA robots isn't without challenges. Their fixed vertical arm limits movement in certain applications. If the workspace layout changes, adjustments may be needed. Additionally, programming these robots can sometimes be complex. Operators must ensure proper training to avoid errors during operation. Attention to detail is key.

In assembly lines, SCARA robots significantly reduce cycle times. They can work alongside human operators effectively. This collaboration, however, requires careful planning. Ensuring safety and efficiency is essential. Balance is crucial, as human oversight is often necessary in complex tasks. The combination of human intelligence and robotic precision can lead to remarkable outcomes.

Collaborative Robots: Enhancing Human-Robot Interaction in Workplaces

In the evolving landscape of manufacturing, collaborative robots (cobots) are making a significant impact. These robots work alongside humans, enhancing productivity while ensuring safety. According to a recent report by the International Federation of Robotics, the global cobot market is expected to grow by over 30% annually. This growth highlights a transformation in workplace dynamics.

Cobots are designed to assist rather than replace human workers. They can handle repetitive tasks, allowing employees to focus on complex problem-solving. However, their integration isn't always seamless. Some employees feel apprehensive about working alongside these machines. Trust and understanding are critical for successful collaboration. To foster this, training programs tailored to both robots and human operators are essential.

Despite their advantages, cobots present challenges. They require regular maintenance and programming. Furthermore, their adaptability to different tasks varies. A rigid workflow can hinder their effectiveness. Investing in flexibility during cobot deployment can yield better outcomes. Organizations must continually evaluate their integration strategies to optimize productivity. Embracing cobots can lead to a more efficient and innovative workplace, but it requires a thoughtful approach.

Related Posts

-

10 Best Intelligent Robot Innovations Changing Our Lives?

-

Transforming Industry with Intelligent Robots at the 138th Canton Fair in 2025

-

Unlocking the Future of Automation with Revolutionary Robot Software

-

Exploring the Future of Robotic Vision: Innovations That Transform Industries

-

Why Robotic Welding Systems Are Revolutionizing the Manufacturing Industry Today

-

What is Robotic Vision? Understanding Its Importance and Applications in Automation